Folding boxes

Have folding boxes printed – from a print run of 1. Your customised folding box packaging will be produced in the format of your choice. Order your folding box online now and have it printed in just a few steps:

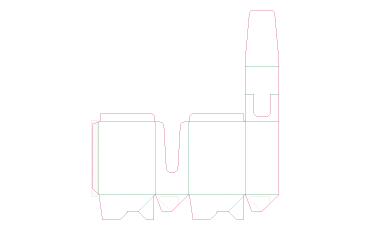

- Select product type: Available as folding box with tuck-in flap (standard) · snap lock base (stable) · crash lock base (extra stable) and other formats.

- Calculate folding boxes online: Quantity & number of types · Format · Cut-out windows (optional) · Production · Cutter size · Material · Printing & finishing · Production time

- Cardboard types: Standard white cardboard · Bright white cardboard · Coloured cardboard · Thicker cardboard · Recycled/natural cardboard – in weights from 215 to 500 g/m².

- Production TimeFrom 3 days

- MaterialGC2 / GC1 / GD2

- Size100% customizable

- Finish OptionsFilm / Varnish / Window

- Online designerCustomised design

- Printing technologyDigital & Offset

Select kind of product

Select base and closure type: Which folding box is right for your product?

If you would like to have folding boxes printed and order them directly online, the type of cardboard and, above all, the type of base/closure determine stability, handling and assembly time. Use our brief overview to help you decide – and then select the appropriate product type in the configurator.

Details on construction, advantages and typical uses can be found below in the section on closure types and base formats.

Definition: What are folding cartons?

Our custom boxes cover a wide range of product packaging, primarily made from cardboard, used as foldable boxes, point-of-sale displays, pillow boxes, hang tabs, or bag boxes. These packaging solutions are used both at the point of sale and in online retail. Folding cartons are employed across nearly every industry and stand out as flexible and functional packaging that provides product information and plays a crucial role in marketing and branding through their design.

Our custom packaging boxes can be tailored to meet your specific branding needs, offering branded boxes that enhance product presentation and reinforce your brand identity. Whether you need custom printed boxes, product packaging, or any other branded packaging, we deliver high-quality solutions with our custom boxes UK.

Discover the diverse applications of our premium folding cartons to elevate your product packaging and stand out at the POS or online.

Advantages of folding boxes

As universally versatile packaging, folding cartons must perform a variety of functions, from product protection to marketing. But these cartons offer many additional features:

- Space-saving flat delivery and storage

- Excellent printability for customised branding

- Easy opening and resealing for consumer convenience

- Aesthetic design aligned with brand identity

- Sturdy stacking in warehouses and on shelves

- Comprehensive protection of products

- Assurance of product quality

- Compatibility with barcodes, labels, and other markings

- Standardised dimensions for sales and transportation

- Eco-friendly, sustainable, and recyclable

Versatile product packaging

Folding cartons have many features that make them a universally adaptable product packaging, different types of folding cartons are suitable for a variety of applications, including:

- Gift boxes

- Chocolate or praline boxes

- Cosmetic boxes

- Jewellery boxes

- Blister packaging

- Gift wrapping

- Retail packaging

- Book covers

- Carton packaging

Our custom packaging boxes can be produced to match your specific branding and size requirements, providing branded boxes that elevate your product presentation. Whether you need custom printed boxes or other branded packaging solutions, we tailor our products to perfectly fit your needs.

Folding cartons for every industry

As a manufacturer of folding cartons, Labelprint24 produces cardboard packaging for nearly all sectors and industries. Besides offering functionality and an aesthetic appearance for your printed folding cartons, we provide many additional benefits:

- Standard sizes (ECMA codes) or completely custom formats

- Online calculation with instant price quotation

- Production and delivery from just 5 working days

Our custom boxes UK cover a wide range of applications, from the pharmaceutical industry and food sector to automotive suppliers and cosmetics. Thanks to their flexible dimensions, various types of folding cartons are suitable for small products like cream tubes, chewing gum packs, or medicine boxes, as well as larger items such as household electronics, clothing, or toys.

Our custom boxes with logo can be tailored to perfectly match your branding, ensuring your products are presented professionally. Explore the wide range possibilities with our branded boxes and custom packaging boxes designed to meet your specific requirements.

In addition to showcasing products at the point of sale, branded packaging has also become increasingly important in e-commerce. When ordering your custom printed boxes, you can select various options and finishes directly via our configurator, including:

- Cardboard materials

- Laser or conventional die-cutting

- Fensterausstanzung (rechtwinklig oder 2 mm Eckenradius)

- CMYK printing for both inside and outside surfaces

- Protective coating (matte or gloss) — optional with cut-out for date or barcode

- Protective laminate (matte, gloss, or soft touch)

- Braille embossing

- Foil stamping (gold, silver, bronze)

| Industry | Examples | Special features |

| Food products | Fruit and vegetables Dairy products Cereals Confectionery Frozen products Pasta Pastries | Protect food from damage, dirt, light, oxygen and moisture Compliance with the legal framework in accordance with EU Regulation 1935/2004 Folding cartons as primary and secondary packaging Brand ambassador with all information on food labelling |

| Pharmaceuticals | Pills Nose drops Bandages Creams Vials Medical technology | Protection against moisture, scratches and particles Secondary packaging for pharmaceutical products incl. package inserts Both high quality and safety standards Compliance with GMP and FDA regulations Serialisation options with labels, 2D codes, barcodes |

| Toiletries | Jars Tubes Bottles Paper towels Nail polish Lotions Mascaras | Protection during transport and storage Aethetic packaging for marketing and customer loyalty Product information on ingredients, best before date, batch number, intended use, etc. |

| Electronics | Smartphones Electrical accessories Cameras Headphones Gaming accessories Computers Household items Toys | Secure packaging for fragile electronic items Products fit perfectly in the box Protection against slipping with the help of packaging inlays Attractive brand design for optimum presentation at the POS |

Online-Designer

With our online designer, you can personalise your selected folding carton by adding your own designs, photos, and logos—or even completely designing your packaging yourself. The available options include:

| Option | Features |

| Text | Multiple text layers possible Large selection of fonts and colours Individual font size and line height Option for rotating, mirroring and bending text |

| Images | Upload your own images 30,000 pattern templates (e.g. seasonal, floral, children, animals, cultures ...) 4.5 million DURST stock photos to choose from |

| Formats | Three basic shapes (rectangle, circle, triangle) Multiple form layers possible Individually configurable in size, fill and outline colour |

| QR-Code | QR-Code / EAN-Code Create QR code directly in the configurator |

| Background | 36 colours directly selectable RGB system / HEX colour codes |

Types of folding carton

From folding cartons with a tuck-in tab, bag boxes, handle cartons, to slipcases and lid cartons, as well as pillow boxes, hanging cartons, or carton sleeves — Labelprint24 has the perfect folding carton for you! To ensure optimal performance, the different construction types, along with closure options and base styles, are crucial factors in selecting the right packaging solution.

Closure types and base formats

| Format | Construction | Advantages | Use |

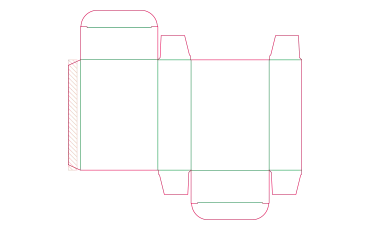

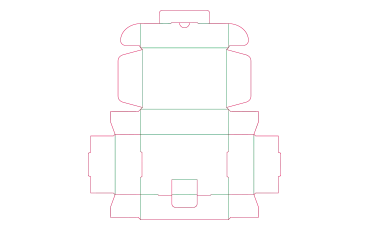

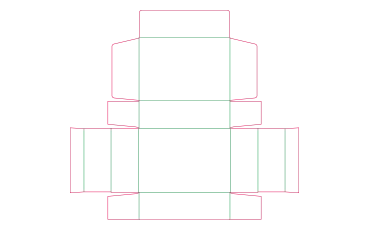

Tuck-in tab  | Closure with two dust flaps and one tuck-in flap. Options: 1. locking closure - two side slots on the tuck-in flap, which are locked by the dust flaps when closing. 2. locking tab - additional small locking tab on the top edge of the box, which is inserted into a slot on the edge of the lid. | No gluing Simple assembly Easy handling Simple delivery and storage | Light and medium-weight products |

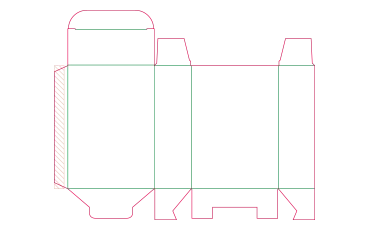

Semi-automatic base  | Bottom closure with four differently shaped flaps that are inserted into each other to close the bottom. The long sides of the box have a C-shaped flap and a trapezoidal flap with an attached rectangle. The side flaps are mirror-inverted pentagons with sloping sides. | No gluing Easy to fit together Easy handling High load-bearing capacity | Medium to heavy products |

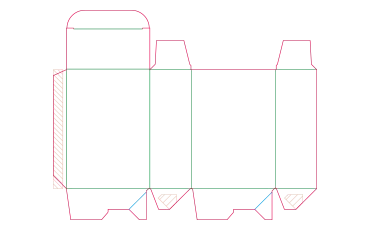

Automatic base  | Closure by two bottom flaps glued and folded together. When the carton is erected, a closed and stable base is automatically created. The 'lightning bottom’ unfolds by applying light pressure to the side walls of the box and can be erected and filled by machine. | For machine filling Easy to assemble Simple delivery and storage Can be constructed by hand | Medium to heavy products |

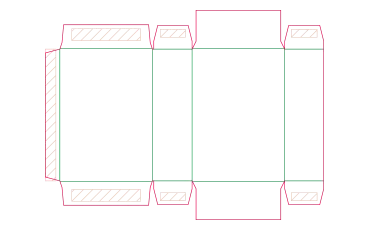

Flap closure  | Base and lid closure with fully overlapping flaps that are automatically glued with adhesive dots when the box is filled. The lid and base construction gives the box additional stability, prevents small parts from falling out and offers great theft protection. | No gluing Secure storage of contents Simple delivery and storage Fully overlapping flaps | Medium to heavy products |

Construction of cardboard in our folding boxes

For folding cartons, types of cardboard with a surface weight (grams per square metre) ranging from about 150 g/m² to 600 g/m² are used. The material consists of multiple layers made from virgin or recycled fibres, including:

- The top layer (outer cover of the cardboard)

- The middle layer and insert (one or multiple fibre layers)

- The back layer (inner cover of the cardboard)

The quality of the product packaging cardboard depends not only on fibre properties but also on a balanced relationship between all the material layers. This multi-layer construction ensures excellent printing, further processing, and finishing. One of the most influential factors are the wood fibres in the cardboard, and their characteristics:

- The fibres form a strong, homogeneous structure

- The fibres create a uniform network

The properties of the fibres allow for the material to be precisely tailored to its intended application, thanks to the different composition of the individual layers. This is achieved by adjusting the ratio of long and short fibres in each layer, ensuring optimal performance for whatever the specific use of the cardboard is.

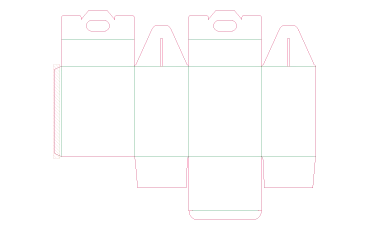

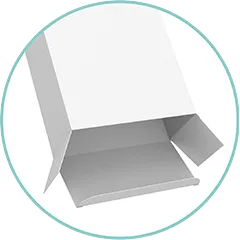

Folding box with tuck-in tab

The folding box with tuck-in tab is the most widely used and cost-effective variant of our printed folding cartons. It features a lid and base closure with two dust flaps and a tuck-in tab with friction lock.

Since the flaps do not always secure the box very tightly, they can be equipped with sealing slits or a locking tongue, ensuring the lid is securely fastened. Folding cartons with a lid are often fitted with safety slits and dust protection to prevent dust and other external particles from entering the packaging.

These custom packaging boxes are frequently used for pharmaceuticals, technical equipment, cosmetics, all kinds of tubes, and small bottles. In the pharmaceutical and medical industries, this product packaging is almost exclusively used for packaging small quantities of medicines or supplements.

Our custom product boxes, including branded boxes and custom boxes with logo, are designed to meet high standards of not only safety, but also branding. Whether for health products or fragile items, these custom printed boxes ensure secure, attractive presentation, reflecting your brand's professionalism and quality.

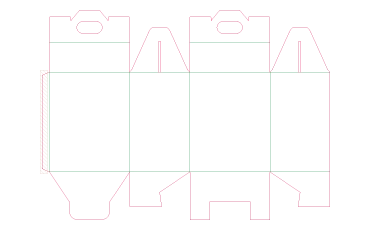

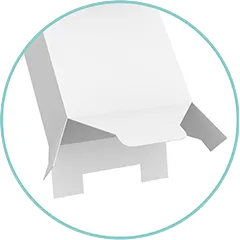

Folding box with semi-automatic base

The foldable box with a semi-automatic base is a special type of tuck-in flap box. The lock bottom consists of a flap on all four sides of the bottom opening. When the box is erected, these flaps fold inward and interlock, securing the contents and preventing them from falling out.

These boxes are predominantly used in industrial packaging for products that require a stable and sturdy base due to their weight. The lock bottom prevents the contents from slipping downward, ensuring the product remains secure during transport and storage.

The packed goods press down on the interlocking tuck-in flaps from above, thereby reinforcing the stability of the base. The lock bottom also ensures a steady stand for the packaging boxes. Unlike the so-called 'automatic base', foldable boxes with a semi-automatic base do not automatically fold out when filled.

These boxes with a lock bottom are commonly used for packaging glass bottles, cosmetic products in glass containers, aftershaves, ceramic items, and beverage cans. Whenever a standard tuck-in flap does not secure the base and product firmly enough, foldable boxes with lock bottom provide a reliable and secure alternative.

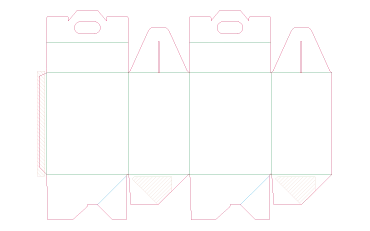

Folding box with automatic base

Automatic bottom folding boxes (also known as crash lock boxes) are a special type of tuck-in flap box. During manufacturing, the bottom is glued, making it exceptionally stable. When the box is erected, the base automatically closes by itself.

The advantage of the automatic bottom is that these boxes can be quickly and reliably filled with goods, whether manually or using machines. Before delivery, the longitudinal seam on one side is glued, and the boxes are supplied flat for easy storage and handling.

Foldable box with flap closure

The foldable box with clasp closure protects your products as a primary or secondary packaging from external influences such as water, dust, light, or scratches. The fully overlapping flaps ensure that the box can be stored safely and space-efficiently on shelves, and can be easily stacked. Additionally, the surface of the box provides ample space for product information and design elements.

The foldable box is partially glued along the longitudinal side with a tab and is only fully sealed at the top and bottom when filled, using an automatic sealing process. Thanks to its securely closed flaps, this type of box offers several advantages:

- Theft protection and secure storage of contents

- Large printable area for product information and branding

- Configurable with window cut-outs and a variety of finishing options

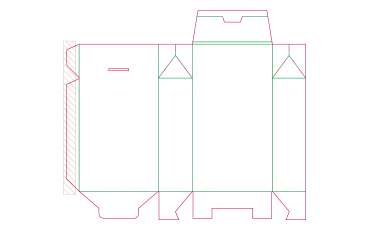

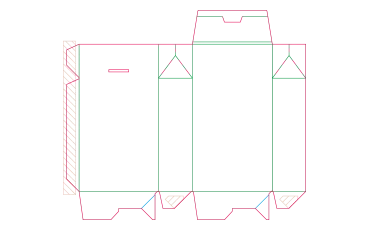

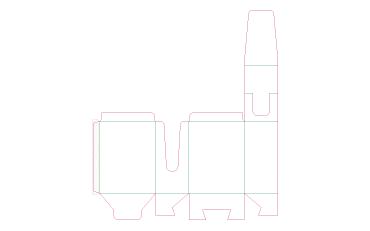

Hanging boxes

The hanging folding box features a sturdy additional flap in the lid with a punched hang hole. This hanging feature is designed for storage to retail display stands, commonly seen in supermarkets, electronics stores, and hardware shops.

Boxes with euro hole hangers are typically used for packaging ink cartridges, metalware, small electronic devices, or toys. The stability of the closure and base can be adjusted according to the weight of the contents, with options such as semi-automatic base, automatic base, cut-in sealing slits, or locking tabs.

Faltschachteln mit Eurolochaufhängung werden typischerweise für die Verpackung von Tintenpatronen, Metallwaren, kleinen elektronischen Geräten oder Spielwaren verwendet. Auch bei Aufhängeschachteln lässt sich die Stabilität des Verschlusses bzw. des Bodens, je nach der Schwere des Inhalts, über einen Steckboden, Automatikboden, eingeschnittene Sperrschlitze oder Schließzungen variieren.

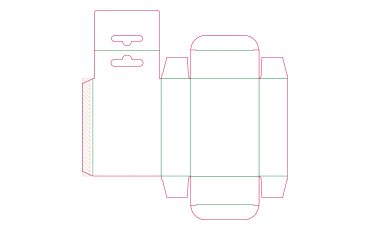

Hanging box with tuck-in tab

Our hanging foldable box with a tuck-in tab is especially suitable for lightweight products. It is available with mirrored flaps, providing a secure and practical solution for product display and transportation.

This versatile packaging option ensures your products are well protected while being easy to hang and showcase.

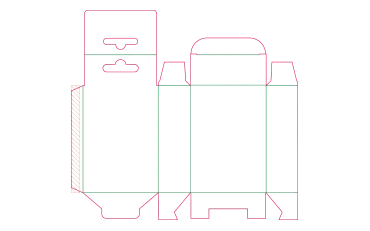

Hanging box with semi-automatic base

The hanging folding box with a semi-automatic base features a sturdy base, making it suitable for medium to heavy products. It can also be ordered with a mirrored flaps for added security and convenience.

This packaging solution provides reliable support and stability, perfect for products that require a more robust structure.

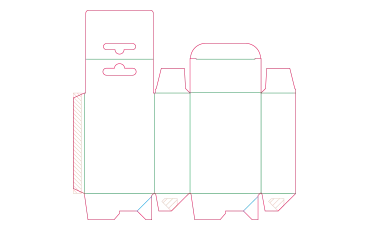

Hanging box with automatic base

The hanging folding box with an automatic base features glued bottom flaps, allowing for quick assembly. It is especially well-suited for machine filling, enabling efficient production and packing processes.

This type of box offers reliable stability and ease of handling, making it ideal for products that benefit from quick setup and secure storage.

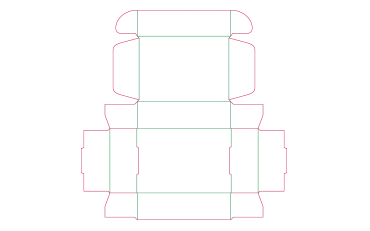

Hinged boxes

Hinged lid boxes are foldable cartons where the lid and base are directly stamped from the carton blank as part of the surrounding sides. Thanks to the large lid opening and side locking flaps, these boxes are easy to open and reseal. They are mainly used for packaging flat items and feature a large surface area on the lid, which can be printed with your brand design or logo to attract customer attention.

This type of box is often chosen for clothing and food packaging — for example, praline boxes, T-shirts, gift articles, or cutlery can all be attractively and securely packed in these versatile cartons.

Standard hinged box

With the insert flaps of our folding boxes, the carton can be closed easily, quickly, and securely. This practical feature ensures your packaging stays closed during transport and display, providing peace of mind along with a professional appearance.

Hinged box with security tab

The extra closure on the insert flap provides additional protection in our folding boxes with security flap. This feature helps prevent accidental opening and ensures the contents remain secure during handling and transport.

One-piece packaging with lid

As a single-piece container with a lid, this box offers an affordable and sturdy alternative to the telescope box. Its simple construction makes it cost-effective while providing reliable protection and stability for various products.

Gable boxes

Gable boxes are cartons featuring a sharply tapered lid in the shape of a gable at the top. This design provides extra stability to the box and makes it especially suitable for fragile products that should not be squished. They make excellent packaging for teas, spices, or sweets, and are also popular as gift boxes. Additionally, they are used for textiles, loose cosmetics, or jewellery.

The box is closed at the gable with an insert flap and has a glued longitudinal seam. For the base, you can choose between a semi-automatic base or an automatic base.

Gable box with semi-automatic base

The gable box with a semi-automatic base combines the distinctive shape of the packaging with the practical advantages of a lock bottom:

- Easy to fill, even from the base

- Large printable surface for your design and logo

- Numerous finishing options and window cut-outs available

- Verpackung zum Wiederverschließen

- Very strong, with simple and quick assembly

Gable box with automatic base

The automatic base gives the aesthetic packaging extra stability and also makes it suitable for heavy goods:

- Extra stable thanks to the glued automatic base

- Automatic closing of the base when erecting

- Easy to fill and reseal

- With optional window punching and many labelling options

Carry handle box

A special type of folding box is the carry handle box. These distinctive cartons are closed using elongated handle flaps that fold together to seal the opening. To secure the handles, the side flaps, which are equipped with slits, are slipped over the handle flaps and lock them in place.

These aethetic and practical custom printed boxes are used at trade fairs, in retail environments, or as presentation packaging for product samples and informational materials. They are easy to carry, can be reopened and resealed, and are available with tuck-in flaps, semi-automatic base, or automatic base for versatile applications.

Carry handle box with tuck-in tab

The carry handle box with tuck-in flap is an attractive gift packaging solution, especially suitable for lightweight products. Its appealing design and practical functionality make it ideal for presenting fragile items or gifts with elegance and ease of handling.

Carry handle box with semi-automatic base

The carry handle box with lock bottom provides secure support even for heavy products while maintaining an aesthetic presentation. Its sturdy design ensures reliable handling and presentation, making it ideal for a wide range of items.

Carry handle box with automatic base

Our carry handle box with an automatic base allows for quick assembly and provides a greater load-bearing capacity. Its efficient design ensures reliable support for various products, making it ideal for both retail displays and shipping.

Counter displays

Counter displays are half-open folding boxes with a flap that can be opened completely and set up. The display’s upright wall transforms into a large presentation surface for the packaged products, which can be attractively positioned directly at the point of sale—whether at the checkout area or on the shelves.

Whether in supermarkets, gas stations, drugstores, or pharmacies, counter displays are quick and easy to set up and are especially suitable for small items like cosmetics, snacks, jewelry or charms, spices, writing tools, or canned drinks. At Labelprint24, you can choose starting from display units with semi-automatic bases or automatic bases, tailored for durable and effective product presentation.

Counter display with semi-automatic base

A counter display with semi-automatic base features four flaps that can be quickly folded together to create a sturdy, durable base. This design ensures reliable support for the displayed products, making it ideal for quick setup and stable presentation.

Counter display with automatic base

Our counter display with an automatic base features glued flaps that provide extra stability and protection. This design allows for quick and reliable setup, ensuring the display remains sturdy during use.

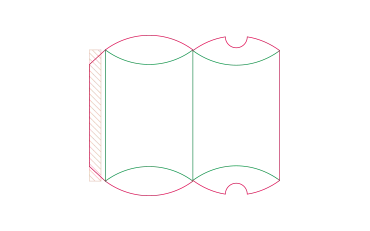

Pillow boxes

Pillow boxes are closed not with tuck-in flaps, but with foldable cardboard flaps that secure the packaging. These pillow-shaped cartons are easy to open and reseal, making them ideal as gift boxes or promotional items. They can be individually customised with your design, logo, slogan, and contact information, turning them into effective advertising media or personalised gift packaging.

Although they primarily serve as promotional carriers and custom gift boxes, pillow boxes also find applications in industry. Thanks to their elegant convex shape, reminiscent of a pillow, they attract particular attention and stand out on shelves. Whether as a branded gift box or industrial packaging solution, personalised pillow boxes pillow boxes are particularly eye-catching for customers.

With their eye-catching, curved shape, pillow boxes are an aesthetic eye-catcher and at the same time provide optimum protection for their contents. These boxes are cost-effective to produce, easy to open, and simple to reseal. They are an ideal, elegant packaging solution for T-shirts, promotional gifts, ear protection, giveaways, and similar items.

Cushion boxes are particularly easy and quick to pack. The printed and unprinted pillow box can also be made open on one side (without a closure). This makes it a popular packaging for products like sandwiches or mini pizzas.

Folding cartons - materials and manufacturing process

Printed folding boxes serve both as a customised advertising tool and at the same time clearly label the product. Large and small printed folding cartons are used everywhere—across industry, trade, and commerce. While each folding box is unique in its shape and function, they are typically manufactured from paper materials such as solid board, carton, or corrugated cardboard.

Discover our different types of cardboard, from white chromo cardboard to bright white GZ cellulose cardboard. Recycled board in various thicknesses and black natural cardboard can also be printed and digitally finished with foil at very low costs.

Our custom product boxes, including branded boxes and custom boxes with logo, are tailored to effectively promote your brand and protect your products. Whether for retail packaging, industrial use, or promotional campaigns, we provide versatile, high-quality solutions.

Materials overview

Depending on the application of your custom printed boxes, different materials are suitable. At Labelprint24, folding cartons are produced from two main types of cardboard: primary fibreboard and secondary fibreboard. We supply either plain (blank) boxes or printed cartons, based on your specific needs. These two types of cardboard are further divided into various grades with different properties. The numbers associated with each grade refer to the respective quality group. When choosing the cardboard types, there are two main fibre types to consider:

- Long fibres – offering high strength and durability

- Short fibres – providing good printability and surface quality

Our high-quality, customised product boxes are manufactured using these premium materials to ensure durability, print quality, and a premium appearance. Whether for packaging delicate products or creating strong, visually appealing cartons, the choice of layered paperboard ensures excellent performance and branding potential.

Primary fibreboard

Cardboards made from wood pulp and cellulose consist of multiple layers: layers of wood pulp interweaved with layers of cellulose on the top and bottom. Primary fibreboards are coated up to three times on the outer surface, while the reverse side is coated once. Secondary fibreboard

These cartons are made from multiple layers of recycled material. However, the top and bottom layers can still be produced from wood-based or cellulose-based fibres. The upper surface of secondary fibreboards is coated three times, while the reverse side is coated once, ensuring good printability and strength.

| GD1 | Coated chromo duplex board / high recycled paper content / grey core & reverse side / white wood-free top side |

| GD2 | Coated chromo duplex board / high recycled paper content / grey core & reverse side / white wood-free or slightly wood-containing top side / white |

| GD3 | Coated chromo duplex board / high recycled paper content / grey core & reverse side / wood-free top side / white |

| GT | Coated chromo triplex board / grey core / at least three layers / white, light or brown reverse side |

Grass cardboard & natural cardboard

Grass paperboard and kraft paperboard hold a special position in terms of appearance, feel, and characteristics. They are appreciated for their natural, eco-friendly look and tactile appeal, making them ideal for premium, sustainable packaging solutions that stand out on the shelf.

Our custom packaging boxes, are crafted from these distinctive materials to provide environmentally conscious branding options, combining aesthetic appeal with strong performance.

| Grass cardboard | Secondary fibre and grass fibre / natural grassy look / recyclable / compostable |

| Natural cardboard | Secondary fibre and primary fibre / rough brown look / environmentally friendly / sustainable |

Production process for custom boxes

Starting from the preparation phase, through the beginning of production to completion, several manufacturing steps must be undertaken. The exact number of steps varies with each order and depends on the intended function of the box, the level of finishing, and any additional processing required.

The pre-press stage

An essential supporting step before printing begins is the pre-press process. During this stage, customer data is prepared for the specific printing system, colour management is carried out, and the printing plates required for conventional printing are produced.

For digital printing jobs, a PDF print file is necessary. Additionally, cutting dies needed for the stamping process are ordered during the pre-press phase or by the order handler.

The printing stage

Once all necessary materials are available, the manufacturing process begins with the printing of the cartons. Depending on the printing method chosen, different steps are required before printing. For offset printing, the cardboard must first be cut to the appropriate format for the offset press.

The offset machine is then prepared with the printing plates, and the inks determined during pre-press are loaded into the ink fountains. After a short initial run, the printer compares the print to a colour-accurate proof for consistency. Once approved, the print job is released for full production. Throughout the printing process, the printer continuously monitors the print quality and makes adjustments to the machine as needed.

Digital printing for custom boxes

Digital printing technologies and the flexibility they offer in production enable a very high degree of customisation and personalisation for custom printed boxes. It's common practice to have small batch sizes, even as low as one. Especially in small runs, ranging from 1 to 15,000 units, with multiple small variants and short delivery times, producers increasingly rely on fast and cost-effective digital printing.

Digital printing of custom boxes isn’t limited to simply printing the boxes; it also includes the entire order process and digital processing and finishing. The entire digital manufacturing process of folded cartons and shipping boxes is data-driven: print data is read directly from the computer via specialised software, processed, and then transferred to other manufacturing devices, such as laser cutters.

This method of data processing offers significant time and cost advantages in the manufacture of foldable packaging: the Non Impact Process (NIP) eliminates the need for printing plates. The costs for custom boxes are generally influenced by several factors: print run size, dimensions, printing method, material, and design. All these factors can be individually adjusted, allowing for tailor-made custom printed boxes.

Offset printing for custom boxes

For larger quantities starting from 1,500 units, offset printing is employed. The range of available carton types, colours, and finishes is considerably broader than with digital printing. Offset printing is particularly used for very high-quality packaging, specially made from fine or superfine corrugated board (E-, F-, or N-flute) or carton.

This method is suitable for medium to high production runs of premium packaging and delivers excellent print quality with great detail and vibrant colours. Our specialised manufacturing processes ensure the precise realisation of your designs—ideal for packaging that elevates your brand and makes a distinctive impact.

Cutting out the contours

The printed and finished sheets are subsequently placed into a flatbed die-cutter. Using a die made from a razor-sharp cutting material, usually a sharpened steel strip, the contours of the folding boxes are cut out. By pressing the sharp-edged cutting tool into the cardboard of the folding box, the paper fibres are cleanly separated.

Generally, paper, card, cardboard, and corrugated board can all be die-cut. When creating a plain folding box (without any print), die-cutting is the first step in processing. The appropriate die for each folding box can always be custom ordered through our folding box calculator at Labelprint24.

Creasing, scoring & die-cutting

In principle, all foldable cartons need to be creased, scored, and die-cut. To enable a clean fold, the printing sheet must first be creased. During creasing, a groove or fold line is pressed into the material, allowing the carton to be folded easily without tearing.

When scoring cardboard, a knife cuts into the outer surface, creating a line that facilitates bending. At scored points, certain sections of the carton—such as tabs or openings—can later be broken out or torn away. After scoring and die-cutting, the blank carton components are broken out and fed into a folding and gluing machine for final assembly.

Gluing & shipping

Since a large proportion of produced foldable cartons with semi-automatic or automatic bottoms need to be erected in automated packaging lines, it is essential that they are easy to construct. Pre-breaking the fold lines softens the creases, making them easier to fold and assemble.

In the final stage of folding carton manufacturing, the die-cut blank pieces are glued at the longitudinal seam or at specific points on the sides. The completed cartons are then shipped to the customer in folded form, ready for filling and use.

Finishing options

We offer a variety of finishing techniques such as hot foil stamping, protective lamination, and UV coatings for your custom boxes. Many of these finishes not only enhance the visual appeal but also provide protective properties, turning your cartons into true eye-catchers.

Thanks to different finishing methods, such as hot foil stamping, you can entirely customise your packaging boxes. Our premium finishing options ensure your packaging stands out on the shelf while offering added protection, making your brand look sophisticated and professional.

Initially, the primary purpose of packaging was its transport and protective function, as goods had to be moved over long distances. A box with a lid had to be sturdy, stackable, and resistant to handling. However, at the start of the 20th century, with the onset of industrialisation, packaging took on new roles—such as convenience, by precisely sizing products into sale units. At the same time, packaging increasingly began to serve as a marketing tool. The rise of supermarkets, self-service shopping, and brand-name products made this function even more significant. Today, packaging is designed not only to protect and transport products but also to attract customers, stand out on shelves, and help shoppers navigate the extensive variety of goods available.

Our custom boxes, including branded boxes and custom boxes with logo, can be crafted to meet these evolving requirements—combining protection, convenience, and eye-catching design to effectively enhance your brand and boost sales.

Since the 90s, the requirements for packaging materials have evolved once again. With a continual increase in consumer environmental awareness, questions regarding disposal and recyclability have become central. Additionally, more information needs to be displayed on packaging surfaces, and also age-appropriate carton packaging has gained popularity, designed to be easy to open yet also securely sealable.

To meet these diverse functional demands, foldable cartons must offer extensive options for product enhancement and finishing. Innovative finishing techniques and tailored design opportunities are essential to delivering packaging that is both practical and environmentally responsible, while also supporting branding and consumer convenience.

.jpeg)

.jpeg)