Paper labels

Are you looking for labels that are suitable for indoor use? Versatile Paper labels with a print in your design? Paper labels from Labelprint24.com mark your products individually and professionally.

- Labels with permanent or removable adhesive

- Large variety of materials and many label types

- Also suitable for outdoor use with protective laminate

Select your Product and calculate it directly online!

- Size100% customizable

- Production TimeFrom 48hr

- Finish OptionsFilm finishing / Varnish / Laminate

- Online designerCustomised design

- Printing technologyDigital & Flexo

Select kind of product

Paper Labels from Labelprint24.com

What are paper labels?

Paper is an environmentally friendly material and is primarily composed of plant fibers. The paper label is printed and used as an information carrier on various objects. Our paper labels can be used in various fields, such as office, warehouse and retail stores to mark products, documents and other items. You can have your labels printed by us with text, images or both. The labels adhere with a previously selected adhesive. There are also differences in the adhesives and can be selected at Labelprint24 according to your wishes.

Labels have become indispensable in everyday use as well as in business. They are a useful tool for organizing and identifying items. The labels can also be used in combination with other marking systems, such as barcodes or QR codes.

What types of Paper Labels are available at Labelprint24?

At Labelprint24 we offer different paper labels. These include white label paper, thermal labels and labels made of recycled paper. We would like to show you these labels in more detail:

Label Paper in white:

Our white paper labels are a classic at Labelprint24. They are multi-talented, as you can use them for labeling or as address and return address labels. Other material properties can be chosen for the white paper labels. You can choose to have the paper in matte or glossy. For the matte paper, we offer permanent adhesive and removable adhesive. The permanent adhesive can also be freezer safe or opaque.

It is also possible to use recycled paper, which can also be ordered with a permanent adhesive. In the product configurator you can also see under "Application examples" for which purpose the labels can be used.

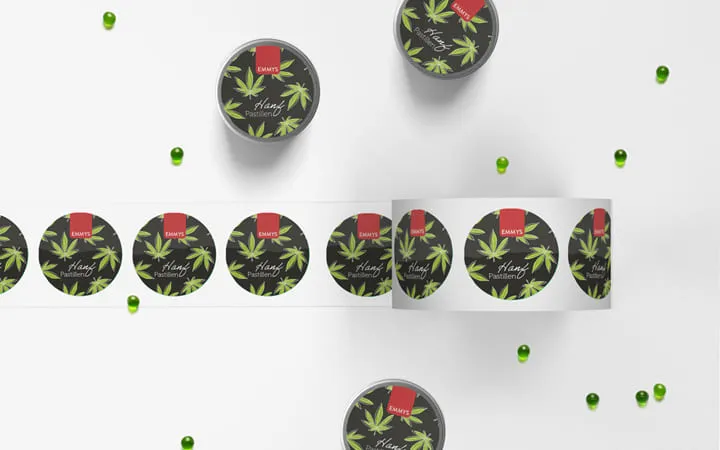

Paper labels are also used in the food trade, for example, when packages need to be labeled.

Material: Label Paper, white + adhesive

Thermal Labels:

You can also get a special type of paper at Labelprint24, the so-called thermal paper. Thermal labels are printed with a thermal printer, no dyes are used for the labeling. The material of the labels is thermo intensive. The labels have a temperature-sensitive layer on the side to be printed. Heat is used to produce a dye, usually black. The labels are permanently adhesive and are available with or without a protective coating for long-term use.

Here, too, the labels can be produced suitable for freezing. Thermal labels are practical for short-term labeling, such as in shipping or retail. Unfortunately, thermal labels are not as durable as film labels, but a thicker paper can increase the tolerance to environmental influences.

This means that the quality of the printed image is retained for longer and fades more slowly.

Material: Thermal Paper - direct printing + adhesive

Recycling Labels:

You can also buy labels made from recycled paper at Labelprint24 and thereby still do something good for the environment. Recycled labels are the most environmentally friendly option among paper labels.

Our recycled paper is available in a matte look and is permanently adhesive. The label paper is popular for organic products.

In addition, our recycled paper consists of 100 percent "Post Consumer Recycled Fibers" and has been awarded the "Blue Angel" eco-label. Our labels are chlorine-free bleached or unbleached, depending on the product.

Metallized Labels

At Labelprint24 we also offer metallized paper labels. As you can see from the name, the labels are still made of paper. However, the surface of these labels is provided with a very thin metal layer. The metal layer is created by "vaporizing" aluminum or another metal using a vacuum process. Thus, these labels also consist of several layers of material.

The outer material is still made of paper, but can also be made of a film (plastic film) depending on the intended use (whether indoors or outdoors). Metallized labels have particularly good barrier properties. The metal is resistant to the following agents:

- Water

- Fat

- Oils

- Chemicals

- Fuels

- Solvent

- Steam

In addition, the metal surface is also resistant to abrasion and reflects light, heat and UV radiation.

With the metallized paper material in gold/silver colors, promotions and price labels as well as promotions can no longer be overlooked. These paper labels with glossy effect are also popular for electronic products. The effect is very close to foil stamping but much more favorable for the customer.

Material: Metallised paper silver / gold + glue

Fluorescent Paper - green / red / orange / yellow

Fluorescent labels can be seen from a distance due to their intense colors. They are used to highlight information or other facts. By the way: The properties of fluorescent labels develop their full potential under UV or black light.

Whether special prices or offers or conventional price labeling - labels with our fluorescent paper are easy to read and decorate in the typical neon colors glued to cardboard boxes and outer packaging many areas of goods labeling.

- available in the colors GREEN/ RED/ ORANGE/ YELLOW

Other Labels

At Labelprint24, besides the well-known labels, we also offer other interesting labels. This is about the laser/inkjet labels. Laser labels are made in such a way that they can withstand strong heat, so that the adhesive continues to stick. The fact is that the equipment used to print the labels generates a lot of heat.

Inkjet printers and inkjet labels reproduce wonderful colors. This makes this type of label ideal for printing images and photos. However, you should be aware that not all types of paper are suitable for this type of label before purchasing them. We will be happy to advise you.

Label paper for laser/ inkjet

- This one-side coated kraft paper has been specially developed for the production of label sheets for copiers and laser printers. The adhesive is particularly suitable for cardboard, PE and PP materials and glass.

Label paper for water-based inkjet printing

Why do we offer (recycled) Paper as a material for our Labels?

At Labelprint24, we also want to offer our customers a large selection of different materials, including paper, of course. Paper is indispensable in both working and professional life. The production of paper is more environmentally friendly than that of plastics, but there is also a need for optimization here.

New or fresh paper (also known as virgin fiber paper) is produced in different ways. In most cases, the paper is made from cellulose, which in turn is obtained from wood. However, a lot of energy and water is needed to extract the cellulose from the wood. In addition, chemical additives are used to separate the fibers from the remaining wood components.

Recycled paper is therefore a good environmentally friendly alternative. Waste paper is used as the base material. The collected waste paper is dissolved with water and the printing ink is removed from the old paper using a chemical. This creates a fiber pulp. The fibers are bleached to give the paper the lightest possible color. Recycled paper therefore also comes in different shades of gray and white, depending on the bleaching process.

No additional wood is needed to produce recycled paper because the paper fibers are simply used again. Paper fibers can be recycled up to 6 times, which reduces the burden on forests and saves 60 percent energy and 70 percent water. Furthermore, less CO2 is emitted and waste is reduced. The chemicals used in production are also less harmful.

Some of the problems associated with recycled paper back then have been eliminated over time and are now only unfounded prejudices. Today's recycled paper is of better quality than it was back then. As a result, the paper can be printed on just as well as virgin fiber paper, and the ink no longer leaks due to the excellent quality. In addition, the papers no longer gather dust thanks to a carefully cut paper edge. The recycled paper also does not yellow faster than virgin fiber paper.

With the "Blue Angel" label, we at Labelprint24 guarantee that the fibers come from 100 percent recycled paper. Thus we grant multiple recycling of papers, also the chemicals are strictly regulated. In addition, the Blue Angel guarantees good "archivability", i.e. the papers are durable for several hundred years.

Coating and finishing of Paper Labels

Would you like to make your labels more resistant and durable to environmental influences with an attractive design? Then we can recommend our coatings and finishes at Labelprint24. Without additional protection, the durability of a paper label is limited. In our product configurator, you can therefore choose between two different coating options.

You can choose between a UV-resistant protective coating or a protective laminate. With both coatings, you have the option of selecting them in matte or glossy. It should be noted, however, that the protective laminate is already transparent.

Coating makes the paper label more resistant to UV radiation, dirt, moisture and humidity, and scratches. If your labels are needed for longer use, we can recommend coating with a clear conscience, especially for outdoor use. The coating also gives your labels an exceptional luxurious or stylish look.

Another way to enhance your paper labels are finishings. Also at Labelprint24 it is possible to have your labels refined. For example, you can choose hot foil stamping in silver, gold and bronze for certain labels. Warning triangles or Braille can also be printed on if required.

Overview of paper types

There are several types of paper, which are distinguished by different manufacturing methods. The different papers are used, for example, as printing or label paper. The individual types of paper differ in the material used, wood-free or wood-containing, which is either coated or uncoated.

One type of paper is wood-free coated paper. It has either a matt, semi-gloss, gloss or high-gloss surface. All details can be reproduced very accurately, sharply and brilliantly on its surface. Fine printing screens are also possible. One type of paper that has gained popularity in recent years is wood-free uncoated paper, also known as uncoated paper. The open, rough surface gives the printed products a pleasant feel with a natural touch. This rough surface ensures that the paper absorbs the printing ink very well and is highly absorbent.

However, too fine printing screens are not possible. Wood-containing coated papers are divided into LWC papers and MWC papers. LWC stands for light weight coated. These are papers with a low grammage that are single-coated on both sides. MWC stands for medium weight coated. This is double-coated paper with a medium grammage. Wood-containing coated paper with very high grammage and high stiffness is MFC (machine finished coated) paper. Wood-containing uncoated papers are machine-finished papers without coating, which are available in various grammages.

Paper production

The production of paper for any printed product, such as magazines, books or labels, takes place in several steps.

The first step is stock preparation. Here, the raw materials used, including the fillers, are topped up with water: the mixture now consists of 99 % water. Subsequently, part of the water is removed from the fiber mixture in the headbox. In the subsequent step, the wire section, a large part of the water runs off and a fiber web is formed.

In the press section, the water is pressed out under pressure. In this step, the water content is reduced from about 75% to about 50%. The paper then passes through the dryer section.

Here, steam-heated hollow cylinders are used to dry and bind the paper. The heat causes the fibers to bond chemically. This gives the paper its final strength. The finished paper has a water content of 5 - 8 %.

Optional steps in paper production are the calender and the supercalender. In the calender, the paper rolls are calendered with several rolls. For calendered surfaces, there is the supercalender. This involves several elastic rolls and steel rolls arranged one above the other. The paper is calendered by means of pressure, heat and friction. This produces a surface that is either matte, semi-matte or glossy.

Properties of different papers

Not all paper is the same. Paper is divided into many types, which have different properties. For various purposes, you need corresponding papers with different properties. We will describe what these properties are in the following.

Paper surface - smooth / rough

One property is the paper surface, which can be smooth or open, i.e. rough. Smooth papers are excellent for printing with brilliant colors. Rough papers, on the other hand, have a special feel.

Brightness

Another property is the paper color, or brightness. Paper in different colors has different effects when printed on. Bright white paper creates a high contrast to the printed image. Creamy white paper is more pleasing to the eye.

But in addition to these two paper colors, there are many others, for example bluish or darker papers with natural coloring. There are various standards and measuring methods for precisely determining the whiteness of a paper, for example DIN standards, D65 or ISO methods.

Surface property: Gloss/ Opacity

Another surface property of paper is gloss. This refers to how much light the paper surface reflects. Matt surfaces have a low reflection, glossy surfaces have a high reflection.

Another light-related property of paper is opacity. This is the light impermeability. If you do not want the printed image to be visible on the reverse side, you should pay attention to a high opacity.

Grammage

Other properties of the paper are the basis weight, also known as grammage, and the volume. The grammage of the paper is given in grams per square meter. A high grammage usually gives paper a high-quality appearance. If you want a lighter paper with a high-quality feel, you can choose a paper with a high volume but a lower grammage.

The ambient moisture content as well as the quality and arrangement of the fibers determine the strength of paper. The strength determines the tensile, burst, bending, surface and tear strength of the paper.

Other paper properties include runnability and printability. These properties are particularly important for the printer and must be considered before printing the paper labels.

What are the advantages of Paper Labels?

The most important advantage of our paper labels is their sustainability. Our labels can be made from recycled waste paper. After our labels have been used, they can be recycled again - creating a cycle.

If you choose white label paper, it is still more environmentally friendly than film labels. Paper is made from wood, a renewable resource. Plastic, on the other hand, is produced with petroleum, and resources are finite. Paper labels are easy to stick, which means that you do not need to use strong adhesives with environmentally harmful ingredients.

In contrast to film labels, paper labels are also easier to write on and print on. Whether pencil, ballpoint pen, laser or inkjet printer and thermal transfer printing, there are many options for labeling our paper labels. Special devices and inks are usually required to print foil labels. This can result in higher costs.

Another advantage of paper labels is the price. Ordinary paper labels are cheaper to buy than the film labels.

Paper labels also have an advantage over film labels in terms of feel and appearance, as they are made from plant fibers. People generally find natural materials more pleasant. We like naturalness, so it is also immediately clear that it is a natural product.

Paper labels have a good marketing effect. Sustainability is not only an important topic for Labelprint24, but also for consumers. Environmental awareness is increasing significantly and has probably never been as high as it is today. Consumers pay attention to how their product has been packaged. Colorful film and high-gloss labels largely indicate plastic.

However, the popularity of plastic has declined in recent years and is considered harmful to the environment. Natural products are therefore increasingly preferred. Rethinking in this area is worthwhile, but of course it always depends on the target group and the product.

Are there any disadvantages to Paper Labels?

Unfortunately, paper labels are less resistant than film labels, especially to moisture. It is possible for paper labels to curl or even peel off completely when wet and damp. We therefore recommend using paper labels indoors or outdoors for shorter periods of time. This is also why film labels are still preferred for frozen food, as condensation forms in the freezer.

Labels that should last a long time and withstand heavy use are made of plastic. As a label manufacturer, we naturally also offer such labels so that you can use your label for every application. Unfortunately, paper is not as durable as plastic, but paper labels have other advantages, for example in terms of environmental protection. Paper labels are also more durable with a protective varnish or protective laminate. Our specialists at Labelprint24 will be happy to advise you.

Where are the Paper Labels used?

Paper labels can be used when the label does not have to be permanent and does not have to withstand certain environmental influences. Such labels are ideal for use in dry indoor areas. They are therefore ideal for food packaging, drinks bottles, letters, folders or cardboard boxes. Sometimes they are also used for chilled products, but the label can curl due to condensation.

Paper labels are also ideal for use as price labels, shipping labels and address labels. A short application of labels is usually sufficient for these examples. In summary, it can be said that the labels can be used optimally in the food industry, in everyday office life or in the mail order business.

Many labels are needed, especially in the office or for organization. Paper labels are particularly easy to write on and are made of paper, so they can be recycled after use.

Instructions for the ordering process for Paper Labels

With the help of our product configurator, it is possible to place orders for paper labels quickly and easily at any time. In the configurator, you can define all the necessary settings for your labels, which are then processed and a concrete price offer is created at the end. If the respective settings are changed, the final price is adjusted immediately.

You can choose between various parameters. Start with the quantity selection and number of types. Here you enter how many labels you require. The number per type is only requested at the end of the order when the data is uploaded.

Next, you can select the material. At Lableprint24, we offer various materials, including different paper labels, but also plastics such as polypropylene (PP), polyethylene (PE) and polyvinyl chloride (PVC). There is also a wide selection of material properties. There you can select the various adhesive properties and whether the paper should be matt or glossy.

Other freely definable parameters are the label shape, the dimensions of the labels, the winding direction and the core diameter of the roll labels.

- Select your paper material and the adhesive properties below.

- Your choice of material is then already selected in the appropriate price calculator.

Finally, you can select a suitable coating or finish for your labels. By entering your data, we can create a production order. With our user-friendly navigation, we offer you an intuitive ordering process. Benefit from our comprehensive service.

If you have any questions about the price calculator, simply contact our customer support.

Our printing processes

We can offer various printing processes for your paper labels at Labelprint24. We recommend digital printing for small and medium print runs. Flexographic printing, on the other hand, is very suitable for larger print runs. We would be happy to present both processes to you in more detail to make your decision easier. However, if you need comprehensive advice, our printing experts are there for you both by telephone and in writing by e-mail.

Flexographic printing process:

The flexographic printing process is also known as the indirect letterpress process. It uses flexographic printing forms, which are particularly elastic. Only a low contact pressure is required for flexographic printing. It is therefore often used in the packaging industry, for example for printing on corrugated cardboard. The printing inks used in flexographic printing are usually environmentally friendly and low-viscosity.

The print motif is located on the printing plates (printing forme, printing forme cylinder). There are several printing units in a modern flexographic printing press. The printing unit consists of an anilox roller and a printing forme (impression cylinder). The anilox roller is used to transfer the printing ink to the printing forme cylinder. This then prints the motif on the impression cylinder, which guides the substrate.

This enables us to achieve optimum printing results for your paper labels.

Digital printing process:

The modern digital printing process (xerography) is often used to print your cardboard or corrugated cardboard packaging, among other things. We also use this printing process for small and medium runs of paper labels.

The digital printing process does not require any fixed print bodies. Data is transferred directly from the digital database (via the cloud or a USB stick) and transferred to the packaging. A particular advantage of digital printing is its cost-effectiveness for smaller print runs. In contrast to the offset printing process, smaller print runs can be printed cost-effectively.

This means that customised labels can be printed for different industries.

After you have successfully placed your order with us, you will be asked to upload your corresponding print data for all products. We look forward to you printing your paper labels at Labelprint24.

Why order from Labelprint24?

As a label manufacturer, Labelprint24 offers you detailed and competent advice. Do you have any questions or other concerns about our labels? Then you can contact our service team by phone or email. Together we will find the right solution for you with our end-to-end service.

As a label manufacturer, Labelprint24 offers you detailed and competent advice. Do you have any questions or other concerns about our labels? Then you can contact our service team by phone or e-mail. Together we will find the right solution for you with our all-round service.

Sustainability is a particular focus for us. We also use recycled or recyclable materials for our paper labels. Labelprint24 wants to make a decisive contribution to the environment and ensure the sustainable use of resources.