Customised boxes by load capacity

Are you seeking a box precisely tailored to the weight of your products? Explore corrugated cardboard shipping packaging available in various load capacities at Labelprint24.com!

- Exact load capacities for maximum stability and efficient transport

- Printed and unprinted in different corrugated types

- High recycled content for sustainable packaging

Choose your product and calculate it directly online!

- Production TimeFrom 5 days

- MaterialE / B / EB flute

- Size100% customizable

- Load capacity10 / 20 / 30 kg

- Online designerCustomised design

- Printing technologyDigital & Offset

Select kind of product

Choosing the right carton based on load capacity

Products vary in format and weight, making it practical to categorise cartons according to their load capacity for both cost-effective and safe transport and storage. Generally, more resistant and stable cartons tend to be more expensive - therefore, it makes little sense to use a high-capacity box of up to 30 kg for delicate items like handkerchiefs, or a cheaper carton with a 10 kg capacity for heavier items such as a hi-fi system.

The basic prerequisite for not exceeding the maximum load capacity is always the even weight distribution of the products within the box. The heavier the goods are, the more the use of additional filling material is recommended. This not only ensures an even load, but also fixes the products inside the box.

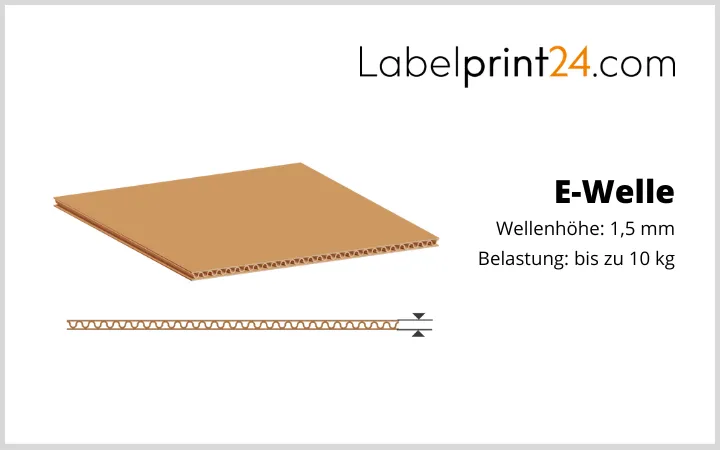

Cartons with a load capacity of up to 10kg

This packaging is made from single wall corrugated board of the "E-flute" type, also known as "microwave." It is ideally suited for light goods such as coffee, tea, and other food items, as well as model kits or headphones. Despite its low load capacity, it provides excellent protection for items weighing up to 10 kg, ensuring safe and cost-efficient transport and storage.

Cartons with a load capacity of up to 20kg

For medium-weight items like bottle containers, musical equipment, cast iron cookware, and small dumbbell sets - boxes with a load capacity of up to 20 kg are ideal. At Labelprint24, we produce these variants using B-flute, a single flute type also known as fine flute. Its strength ensures that products do not slip through the bottom or cause the packaging to bend, maintaining stability for safe and efficient storage.

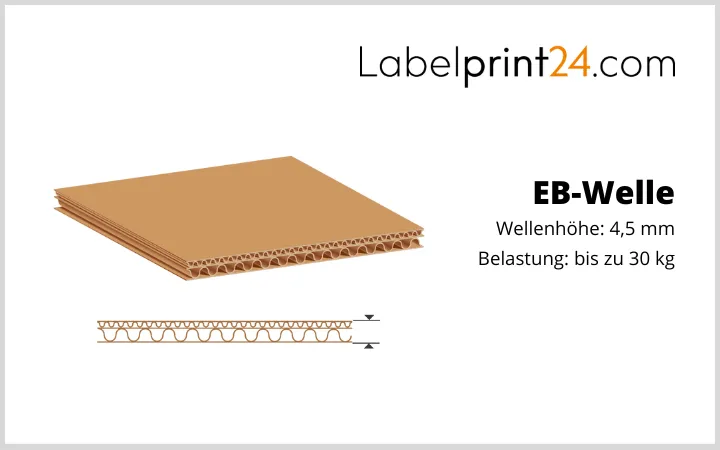

Cartons with a load capacity of up to 30kg

If your products include machine parts, large televisions, or professional speakers, our boxes with a load capacity of up to 30 kg are the perfect choice. These are made from double flute corrugated board, specifically EB-flute, which combines E-flute and B-flute layers. The two types of corrugated are bonded with a smooth intermediate layer. This design offers exceptional robustness and printability — with the fine, smooth E-flute serving as the outer wall, while the more stable B-flute forms the inner layer. As a result, cartons with EB-flute are ideal for aesthetic and durable product packaging that can protect heavier goods.

Advantages of differentiating by load capacity

Differentiating cartons according to their load-bearing capacities offers several benefits:

Protective function

Selecting your board based on it's load capacity helps provide the optimum protection for your products. For lightweight, non-fragile items, single flute cardboard is typically the most cost-effective and suitable option. Known as fine flutes, they have a flute height of 3.0 mm and a pitch of 4.8 mm. The load-bearing capacity reaches up to 10 kg with E-flute and 20 kg with B-flute, provided the weight is evenly distributed - ensuring adequate protection for your contents. However, because of the small air cushions and fine flute structure, this type of board offers less protection against pressure or falls compared to larger flutes. For heavier or more fragile goods, we would recommend double flute EB corrugated board with a maximum load capacity of up to 30 kg.

Storage

Cartons are typically stored in stacks, and their load capacity directly influences how well they can be stacked and how much pressure they can withstand. From a logistical perspective, it is sensible to differentiate cartons based on their load-bearing capacity. Choosing a carton with too low a load capacity can result in the bottom of the stack breaking when lifted, or cartons stacked beneath to fail under the weight of the upper ones. This can lead to damage, delays, and additional costs. Properly selecting cartons according to their load capacity helps ensure safe, efficient storage and transportation.

Costs

Cost efficiency is essential for every company and must be continuously optimised. In logistics, it’s important to evaluate whether the choice of product or shipping cartons aligns with your actual load requirements, or if there is potential for savings. Selecting oversized cartons with higher load capacities than necessary for lightweight or robust goods can lead to significant costs overtime. Therefore, it is crucial to precisely calculate the minimum required load capacity of your cartons to ensure optimal protection, storage, and cost management.

Diverse carton selections at Labelprint24

At Labelprint24, you will find a wide variety of cartons with different load capacities, each determined by the selected material. For all models, you have the choice between E-, B- and EB-flute options.

Classic folding box with tuck-in flap

The folding box with tuck-in flap is a classic in product packaging, known for its easy handling and suitability for automatic filling. It is commonly used for food products such as noodles or cornflakes. At Labelprint24, you can also select this design with offset flaps (FEFCO 0211) or with opposing flaps (FEFCO 0211).

Hinged lid box for premium products

Our hinged lid box is even more user-friendly thanks to the easy-to-open hinged lid, making it especially popular with customers. This enhances the unboxing experience, which can be further personalised by fully printing the inside of the box's lid. It is ideal for high-value items such as cosmetics or jewellery.

Sturdy FEFCO 0215 folding box with semi-automatic base

Thanks to its design, the FEFCO 0215 folding box with a semi-automatic base is perfectly suited to particularly heavy goods. With a user-friendly design, the base is securely plugged together and thus offers excellent stability. This model is commonly used as packaging for spirits and other heavy products.

Automatic base folding box (FEFCO 0713)

The folding box with an automatic base, type FEFCO 0713, is similar in design but features a pre-glued bottom that automatically assembles when unfolded. It offers the same stability as the semi-automatic base model but is even easier to handle.

E-commerce shipping carton with automatic base

Our shipping carton with an automatic base and adhesive strip is particularlu suited to e-commerce. It is sealed prior to dispatch using the pre-applied adhesive, and the customer can very simply tear along the perforated line to open.

Diverse paper types for corrugated board

We utilise various types of paper in our corrugated board production, which can be differentiated according to the desired strength, cost considerations, and intended application.

Bogus paper

Bogus paper is a lightweight liner paper with a grammage of up to 140 g/m². Typically produced from recycled paper, it is mainly used as an intermediate liner for double-wall corrugated board.

Testliner paper

Tesliner paper is also mainly produced from recycled paper, but additionally from corrugated board scrap, this type of paper is multi-layered and has a grammage of up to 200 g/m².

Kraft liner paper

Unlike the previously mentioned materials, kraftliner typically contains a high proportion of virgin fibres, giving it excellent stability. Virgin fibres are longer than recycled fibres, allowing them to interlock stronger. With a grammage of up to 400 g/m², kraftliner is mainly used for packaging very heavy goods. Additionally, the high virgin fibre content enables better adhesion of packaging tapes. Kraftliner paper is also relatively easier to print on compared to other materials.