Sustainability Standards in Packaging Materials : Responsible Practices for Modern Businesses

Key Takeaways:

- Different packaging materials offer varying degrees of environmental performance and protection capabilities

- Kraft paper pouches provide excellent protection with reduced material usage while offering a natural aesthetic appeal

- Corrugated cardboard boxes meet international FEFCO standards for strength and durability across multiple weight capacities

- Customisable packaging solutions can optimise material efficiency while maintaining brand consistency

- Recyclable and biodegradable options are increasingly available for various packaging needs, reducing environmental impact

- Paper labels offer responsible alternatives to traditional plastic options with comparable performance characteristics

- Right-sizing packaging can significantly reduce material usage and shipping costs simultaneously

- Expert consultation can help businesses navigate complex packaging material decisions

Introduction to Responsible Packaging Materials

In today's business environment, packaging decisions have far-reaching implications beyond simple product containment. The materials chosen for product packaging impact product protection, presentation, and environmental considerations throughout the entire supply chain and lifecycle. As consumers become more environmentally conscious, businesses are looking for packaging solutions that minimise environmental impact while maintaining functionality and brand appeal.

At Labelprint24, we understand the importance of responsible packaging choices in today's marketplace. Our range of packaging solutions helps businesses meet their packaging needs while following responsible material practices that align with modern environmental standards. From stand-up pouches to durable corrugated cardboard boxes made to precise specifications, we offer options that balance performance with environmental considerations without sacrificing quality or protection.

This article explores the various standards and considerations for packaging materials, highlighting responsible options available for businesses today across multiple industry sectors. We'll examine different material types, their unique properties, environmental profiles, and how they can be used effectively in various packaging applications to maximise both protection and sustainability. By understanding these options, businesses can make informed decisions that satisfy consumer expectations while minimising environmental impact.

Understanding Packaging Material Standards

Packaging materials are subject to various standards and regulations that ensure their safety, functionality, and environmental performance throughout the product lifecycle. These standards guide manufacturers and businesses in selecting appropriate materials for their specific needs while ensuring compliance with industry best practices and regulatory requirements across different markets.

Key Standards for Packaging Materials

Several international and regional standards govern packaging materials, creating a framework for quality, safety and sustainability:

1. ISO Standards - The International Organisation for Standardisation provides guidelines for packaging materials, including testing methods and environmental considerations. ISO 14001 addresses environmental management systems, while ISO 18601-18606 covers various aspects of packaging and environment, from general requirements to organic recycling and energy recovery.

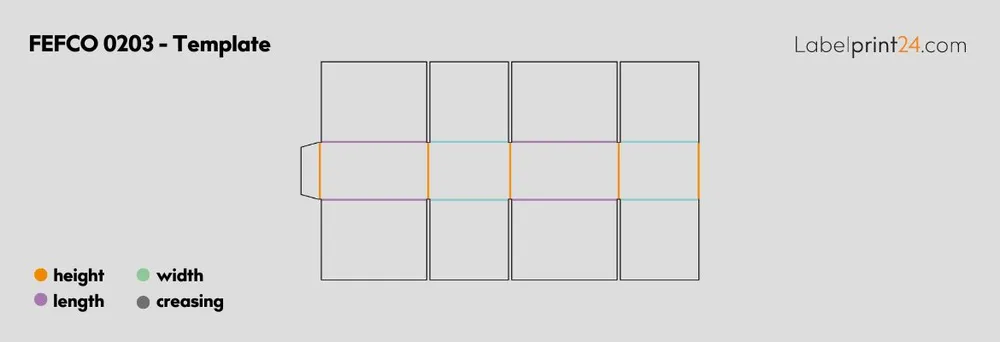

2. FEFCO Standards - The European Federation of Corrugated Board Manufacturers sets standards for corrugated cardboard packaging, defining various box styles and construction methods through an internationally recognised coding system. These standards ensure consistency in design, structural integrity, and performance across the industry, making specification and ordering processes more efficient.

3. Food Contact Material Regulations - For food packaging, materials must comply with specific regulations ensuring they don't transfer harmful substances to food products. In Europe, Regulation (EC) No 1935/2004 establishes the fundamental principles, while in the US, the FDA regulates food contact materials through various provisions in the Federal Food, Drug, and Cosmetic Act.

4. Recyclability Standards - Various certifications indicate the recyclability of packaging materials, helping businesses make informed choices. These include the Recycling Symbol (Möbius loop), the Green Dot system in Europe, and specific certifications like FSC (Forest Stewardship Council) for paper-based materials.

Understanding these standards helps businesses select packaging materials that not only protect their products but also align with responsible practices and regulatory requirements across different markets. For example, our FEFCO 0203 boxes are designed according to international standards, providing reliable protection while using materials efficiently through their full-overlap design that enhances stacking strength and product security during transportation and storage.

Paper-Based Packaging Materials

Paper-based packaging materials represent one of the most widely used and environmentally responsible options available in today's packaging landscape. These materials offer flexibility, excellent recyclability, and outstanding printability for branding purposes, making them suitable for a wide range of applications across multiple industries. With increasing consumer preference for sustainable packaging, paper-based solutions have seen significant innovation in recent years.

Corrugated cardboard is a fundamental staple in the packaging industry, known for its exceptional strength-to-weight ratio and superior protective qualities. The structure of corrugated cardboard, with its engineered fluted middle layer sandwiched between sturdy liner sheets, provides excellent cushioning, impact resistance, and stacking strength while remaining relatively light compared to alternative materials.

Corrugated Cardboard Boxes

Our corrugated cardboard boxes come in various engineered flute profiles, each offering different characteristics tailored to specific packaging requirements:

E-Flute:

Fine fluting provides excellent printing surfaces and is suitable for lighter items up to 10kg. With approximately 90 flutes per metre, E-flute offers superior surface smoothness for high-quality graphics while maintaining good cushioning properties.

B-Flute:

Medium fluting offers good cushioning and stacking strength for items up to 10kg. With approximately 150 flutes per metre, B-flute provides an excellent balance between protection and material efficiency.

EB-Flute:

Combined fluting provides enhanced strength for items up to 30kg. This double-wall construction combines the advantages of both E and B flutes, delivering superior compression strength and puncture resistance for heavier or more delicate items.

The FEFCO 0211 folding boxes are particularly popular for their tuck-in flap design, which provides secure closure without additional sealing materials such as tape or adhesives. This design minimises material usage while maintaining excellent functionality, making it both cost-effective and environmentally responsible. The self-locking mechanism ensures products remain secure during transport while making it easy for end-users to open and reclose.

Folding Cartons and Speciality Paper Packaging

Beyond standard corrugated boxes, paper-based packaging includes folding cartons and speciality designs that cater to specific product needs and marketing requirements. These premium options often use solid paperboard rather than corrugated materials, offering an elegant feel and exceptional printability for high-end products and retail environments where presentation is important.

Our folding boxes with snap lock bases offer convenience and security for products of various weights and dimensions. The snap lock mechanism ensures the box remains securely closed during transport and storage without requiring adhesives or tape, making both assembly and recycling easier. These boxes can be produced with various finishing options, including glossy, matte, or speciality coatings to enhance visual appeal and brand recognition.

For flat items such as documents, photographs, or thin electronics, our flat cardboard sleeves with snap fasteners provide excellent protection while using minimal materials. Available in grammages ranging from 215 to 500 g/m² to accommodate different protection requirements, these sleeves can be customised to suit specific product dimensions and branding requirements. The secure snap fastener ensures contents remain protected while allowing easy access when needed.

Flexible Packaging Solutions

Flexible packaging represents a significant advancement in packaging efficiency and versatility, offering exceptional product protection while using substantially less material than rigid alternatives. These solutions are particularly valuable for food products, cosmetics, pharmaceuticals, and other items requiring specific barrier properties against moisture, oxygen, light, or contaminants. The reduced material usage means lower shipping weights, decreased storage space requirements, and improved sustainability metrics across the supply chain.

Stand-Up Pouches

Stand-up pouches have gained tremendous popularity across multiple industries for their versatility, outstanding shelf appeal, and exceptional material efficiency. These pouches stand upright independently on store shelves, maximising visibility and brand presentation while providing excellent product protection through multiple barrier layers. Their space-efficient design allows for more efficient transportation and storage compared to rigid containers, reducing both costs and environmental impact.

Our stand-up pouches come in various configurations to meet different product requirements and consumer preferences:

- Standard Stand-Up Pouches: Basic design suitable for most products, featuring high-barrier materials that protect against moisture, oxygen, and light while maintaining product freshness

- Pouches with Windows: Incorporate transparent panels that allow consumers to see the product inside, enhancing consumer confidence while maintaining necessary barrier properties in critical areas

- Pouches with Zippers: Feature resealable closures that provide convenience for repeated use, extending product freshness after opening and improving the overall consumer experience

All our stand-up pouches with windows and zippers are manufactured to meet food safety standards, ensuring they are food-safe, odourless, and tasteless, making them ideal for a wide range of food products from coffee and tea to snacks and confectionery. They provide barrier properties against oxygen, carbon dioxide, moisture, and flavour transfer, ensuring product freshness and extended shelf life compared to conventional packaging. The high-quality printing capabilities allow for vibrant, full-colour graphics that enhance brand recognition and consumer appeal.

Kraft Paper Pouches

For businesses seeking paper-based flexible packaging with a natural look, our kraft paper pouches offer an excellent alternative to conventional plastic options without sacrificing functionality. These pouches combine the warm, authentic appearance and feel of kraft paper with the performance characteristics of modern flexible packaging, creating a solution that appeals to environmentally conscious consumers while delivering reliable product protection.

Our kraft paper stand-up pouches with zippers offer multiple benefits for both businesses and consumers:

- Food-safe, odourless, and tasteless construction that complies with all relevant food contact regulations

- Available with specialised barrier layers that protect against oxygen, carbon dioxide, moisture, and flavour transfer while maintaining the natural paper exterior

- Suitable for a diverse range of products including solid items, pastes, powders, and liquids of varying viscosities

- Resealable with convenient zipper closures that maintain product freshness after opening and enhance consumer convenience

- Available in multiple sizes from 100ml to 1000ml to accommodate different product quantities and packaging needs

Speciality Packaging Solutions

Beyond standard boxes and pouches, speciality packaging solutions address specific product requirements, marketing objectives, and retail environments with tailored designs and material combinations. These solutions often combine different materials, structural elements, and design features to create packaging that stands out in competitive retail environments while maintaining optimal functionality and protection throughout the supply chain and consumer use.

Retail Display Packaging

Retail display packaging serves the dual purpose of protecting products during distribution and showcasing them effectively at the point of sale. These solutions are designed to attract consumer attention, communicate brand values, facilitate product examination, and ultimately drive purchase decisions in competitive retail environments where shelf presence can significantly impact sales performance.

These pouches offer the rustic, natural appearance of kraft paper that appeals to today's environmentally conscious consumers while providing the functionality needed for modern product packaging and protection. They've become particularly popular for organic products, speciality coffee, premium tea, artisanal nuts, dried fruits, and other natural food items where packaging appearance plays a crucial role in communicating product values and quality.

Our counter displays with snap lock bases feature several design elements that enhance both functionality and marketing effectiveness:

- Advertising-effective rear walls that double as retractable packaging lids, maximising brand visibility while providing product protection

- Precision-engineered insertable bottoms that can reliably support even heavy products without compromising structural integrity

- Full compliance with the internationally recognised ECMA FC0603 standard, ensuring consistent quality and performance

- Highly customisable designs that maintain brand consistency across product lines and retail environments

- Space-efficient construction that maximises product visibility while minimising footprint on valuable retail counter space

For products requiring additional security during transport, handling, and display, our boxes with safety flaps provide increased stability and tension through their specialised design. These boxes are available in a range of cardboard options to meet different aesthetic and functional requirements, including premium white, coloured, natural kraft, bright white, and recycled materials, with carefully selected grammages specifically suited to different product weights and protection needs.

Labelling Solutions for Responsible Packaging

Labels play a crucial role in packaging systems, providing essential product information, reinforcing brand identity, ensuring regulatory compliance, and often enhancing overall package functionality. Responsible labelling solutions consider both the label materials themselves and their compatibility with package recyclability to ensure the entire packaging system maintains environmental performance throughout its lifecycle.

Paper-Based Labels

Paper labels offer a responsible and versatile alternative to plastic labels for a wide range of applications across multiple industries. These environmentally preferable labels can be manufactured from various specialised paper stocks, including recycled materials, uncoated papers, and coated options, each engineered to meet different performance requirements from basic identification to premium product presentation in challenging environments.

Our paper labels are available in a range of specialised materials to meet diverse application requirements:

- Premium white paper for standard applications requiring excellent printability and visual appeal

- Specialised thermal paper for variable information printing in logistics, retail, and inventory management applications

- Recycled paper options with post-consumer content for enhanced environmental performance and sustainability messaging

- High-visibility fluorescent paper for safety applications, promotions, and attention-grabbing product highlights

- Textured and speciality papers that provide tactile elements enhancing perceived product value

These labels can be equipped with different adhesive technologies carefully selected for specific application requirements, including permanent adhesives for one-time application, removable adhesives that leave no residue, deep-freeze suitable adhesives for cold chain applications, and speciality adhesives for challenging surfaces or environmental conditions. This flexibility ensures optimal performance across diverse packaging applications while maintaining responsible material choices.

Optimising Material Usage in Packaging

Beyond careful material selection, optimising material usage represents a key aspect of responsible packaging practices that can deliver significant environmental and economic benefits simultaneously. By minimising material consumption while maintaining or even enhancing product protection, businesses can reduce both environmental impact and packaging costs throughout their supply chain, creating value for both the business and its customers while supporting sustainability objectives.

Right-Sizing Packaging

Right-sizing involves the design and engineering of packaging to match product dimensions with precision, eliminating excess material and unnecessary void space. This approach not only reduces material consumption but also improves shipping efficiency by reducing package volume and weight, leading to lower transportation costs, reduced carbon emissions, and more efficient use of warehouse and retail space throughout the distribution chain.

Our custom-made shipping box service enables businesses to create packaging that fits their products with precision, eliminating the wasteful practice of using oversized standard boxes with excessive void fill materials. By working with our design engineers, businesses can develop optimised packaging solutions that balance protection requirements, presentation objectives, and material efficiency. This customisation process considers factors such as product fragility, distribution environment challenges, and handling requirements to ensure adequate protection while minimising material usage.

Material Reduction Strategies

Beyond basic right-sizing, several strategies can help significantly reduce material usage in packaging without compromising essential protection or functionality:

- Lightweighting: Using engineering techniques to use thinner materials where possible without compromising structural integrity or protection capabilities. This approach often involves using higher-performance materials that deliver equivalent or superior protection with less mass.

- Structural Design: Implementing innovative structural designs that provide enhanced strength with less material through geometric optimisation. Techniques such as strategic scoring, folding patterns, and reinforcement placement can maintain or improve performance while reducing overall material content.

- Material Substitution: Replacing heavier materials with lighter alternatives where appropriate based on detailed performance analysis. This might involve substituting glass with certain plastics or metals with fibre-based materials in specific applications.

- Elimination of Unnecessary Components: Analysing packaging systems to identify and remove non-essential packaging elements without affecting core functionality. This might include simplifying closure systems, combining multiple components, or rethinking traditional packaging approaches entirely.

Our flat pouches show material efficiency principles in action, providing excellent product protection with minimal material usage through their streamlined design. These pouches are available in various high-performance materials and calibrated thicknesses, allowing businesses to select the optimal option for their specific product requirements without excess material. The flat design also maximises shipping and storage efficiency compared to rigid containers, further reducing environmental impact throughout the supply chain.

Expert Consultation for Packaging Material Selection

Selecting the optimal packaging materials involves balancing multiple factors, including product protection requirements, presentation objectives, cost considerations, and environmental impact throughout the product lifecycle. Expert consultation can help businesses navigate these decisions effectively and develop packaging solutions that meet their specific needs while avoiding common pitfalls that can lead to overpackaging, underperformance, or unnecessary costs.

Our expert consultation service for pouch packaging helps businesses maximise product protection and presentation with minimal material usage through informed design decisions. Our product advisors bring specialised knowledge of material properties, barrier requirements, filling processes, and consumer usage patterns to guide you through the selection process. They can provide guidance on material options, structural design considerations, and production processes to develop packaging that meets your specific requirements while optimising both performance and sustainability.

When selecting packaging materials, consider these critical factors that our experts evaluate during the consultation process:

1. Product Requirements: What specific level of protection does your product need based on its physical characteristics and vulnerability? Does it require specialised barrier properties against moisture, oxygen, light, or other environmental factors? Are there product-specific considerations such as oil resistance, temperature stability, or compatibility issues that must be addressed?

2. Distribution Environment: Will the packaging face particularly challenging conditions during shipping and handling, such as temperature extremes, high humidity, stacking pressure, or frequent handling? How will the packaging perform throughout various transportation modes and storage conditions in your specific supply chain?

3. Retail Requirements: How will the packaging need to perform in retail environments? Does it need specific capabilities to stand independently, hang from displays, or stack efficiently? What shelf presence characteristics are most important for your product category and target market positioning?

4. Consumer Expectations: What packaging attributes and functionalities are most important to your specific target consumers? Are convenience features like resealability, portability, or dispensing mechanisms critical to product satisfaction? How does packaging align with your brand values and consumer perceptions?

5. End-of-Life Considerations: How will consumers typically dispose of the packaging after use in your target markets? Are recycling systems readily available for your chosen materials? Would compostable or biodegradable options be appropriate and beneficial for your specific application and market context?

By evaluating these factors with expert guidance and technical knowledge, businesses can develop optimised packaging solutions that effectively balance performance requirements, cost considerations, and environmental impact across the entire product lifecycle, avoiding both overpackaging and underprotection while meeting consumer expectations.

Conclusion

Responsible packaging material choices represent a critical strategic aspect of modern business operations that impacts everything from product protection and consumer experience to brand perception and environmental footprint. By carefully selecting appropriate materials based on specific product requirements, optimising material usage through thoughtful design, and continuously seeking improvements as technologies evolve, businesses can develop packaging solutions that protect products effectively while minimising environmental impact throughout the product lifecycle.

At Labelprint24, we offer a comprehensive range of packaging solutions designed with responsibility and performance in mind. From our corrugated cardboard boxes engineered to meet international standards to our flexible pouches that minimise material usage while maintaining excellent protection, our diverse product portfolio helps businesses balance performance requirements, presentation objectives, and environmental considerations in an increasingly sustainability-focused marketplace.

We invite businesses of all sizes and across all industries to explore our range of packaging solutions and consult with our packaging experts to develop tailored packaging that meets their specific requirements and sustainability objectives. With the right materials, thoughtful design, and proper implementation, packaging can fulfil its essential protective and marketing functions while aligning with responsible business practices and environmental stewardship principles that increasingly matter to consumers, retailers, and regulatory bodies worldwide.

For personalised assistance with your packaging challenges and opportunities, contact our expert consultants who can guide you through the entire process from material selection and structural design considerations to production options and implementation strategies. Together, we can develop optimised packaging solutions that work effectively for your products, your business operations, and the environment while enhancing your brand's reputation for responsibility.

By making thoughtful, informed choices about packaging materials, design, and implementation, businesses can protect their products effectively while showing their commitment to responsible practices that influence consumer purchasing decisions. At Labelprint24, we're proud to support businesses across industries with our range of high-quality, responsible packaging solutions backed by expert consultation and reliable service throughout the entire packaging development and production process.