Labelling Compliance for Pharmaceutical Products: Essential Requirements and Best Practices

Key Takeaways

- Pharmaceutical labelling must follow strict rules to keep patients safe and products secure throughout the supply chain

- Proper pharmaceutical labels include important information like dosage, ingredients, warnings, and usage instructions for healthcare providers and patients

- Tamper-evident packaging protects against product tampering while building consumer trust and meeting legal requirements

- Multi-layer labels provide extra space for regulatory information without making packaging bigger, which helps in markets with multiple languages

- Following GHS/CLP regulations is required for chemical components in pharmaceuticals, with specific warning pictures and hazard statements

- High-quality printing and materials make sure pharmaceutical labels stay readable and intact throughout the product's life

Introduction to Pharmaceutical Labelling Requirements

Pharmaceutical labelling is one of the most heavily regulated types of product packaging. Labels are the main way manufacturers communicate with patients, healthcare providers, and regulatory authorities. At Labelprint24, we know pharmaceutical companies face many challenges in meeting these requirements while keeping their brand identity and product security.

The pharmaceutical industry must follow many regulations that control everything from ingredient lists to warning statements. Labels must give clear, accurate information for safe usage while meeting standards set by agencies like the FDA and EMA. These rules are often updated to address safety concerns, new scientific findings, and international standards, so manufacturers must stay alert and ready to adapt.

Pharmaceutical labels must include specific elements like active ingredients, dosage instructions, warnings, contraindications, batch numbers, expiration dates, and manufacturer information. The challenge is presenting all this information clearly and legibly while dealing with limited space on packaging. Labels must also stay intact throughout the product's life, often in tough conditions including temperature changes, moisture, and frequent handling.

Multi-layer label solutions have become very important for pharmaceutical companies that need to include lots of information in limited space. These special labels allow manufacturers to follow regulations without needing larger packaging. These labels provide multiple readable surfaces while looking professional and making sure critical information stays accessible throughout the product's life cycle.

Core Components of Compliant Pharmaceutical Labels

Every compliant pharmaceutical label must include several essential parts that ensure patient safety and meet regulations. Understanding these requirements is important for manufacturers who want to avoid recalls or penalties. The design and content of pharmaceutical labels are carefully regulated to ensure consistency, clarity, and completeness of information across all products.

Required Information Elements

Pharmaceutical labels must include:

- Product name (both brand and generic) - clearly displayed so people can identify it correctly

- Active ingredients and their quantities - stated precisely in proper units of measurement

- Dosage instructions and administration routes - detailed guidance about when, how often, and how to take the medicine

- Warnings and contraindications - clearly highlighted information about risks, side effects, and when not to use the product

- Storage requirements - specific temperature ranges, light exposure limits, and humidity considerations

- Batch/lot numbers and expiration dates - traceable manufacturing information and clear indication of how long the product is good for

- Manufacturer information and contact details - company name, address, and how to report problems

- Barcode or tracking information - machine-readable data for inventory management and authentication

The format of these elements isn't random—regulatory agencies specify requirements for font size, contrast, and placement to ensure readability. Warning statements typically need to stand out through bold text, colour highlighting, or specific positioning. The FDA requires minimum font sizes for critical information and some warnings must appear in bordered boxes to make them more visible. These formatting rules help make sure even patients with poor eyesight can read essential information.

Chemical labelling requirements add more complexity for pharmaceutical products with hazardous substances. These must follow GHS (Globally Harmonised System) and CLP (Classification, Labelling and Packaging) regulations, which require specific warning pictures, signal words, and hazard statements. These standard elements ensure consistent communication of chemical hazards across different countries and languages.

Material and Printing Considerations

- Resistance to moisture, chemicals, and temperature changes - making sure information stays readable even when exposed to humidity, cleaning agents, or temperature changes

- Adhesive quality that prevents peeling but allows clean removal if needed - balancing permanent attachment with the potential need for repositioning

- Compatibility with sterilisation processes for certain products - maintaining integrity when exposed to sterilisation methods

- Durability to withstand handling and transportation - resisting damage throughout distribution

At Labelprint24, we offer specialised thermal transfer printing solutions that ensure consistent, high-quality print results for pharmaceutical labels. Our thermal transfer ribbons provide excellent durability and resistance to environmental factors. These printing technologies deliver precise, high-resolution output that stays clear even for small text and complex symbols, making sure all required information remains readable throughout the product's shelf life.

Tamper-Evident Packaging and Security Features

In the pharmaceutical industry, product security is extremely important. Tamper-evident packaging and security features on labels help protect consumers and maintain the integrity of pharmaceutical products. These features have become more sophisticated to address concerns about counterfeiting, diversion, and tampering in global pharmaceutical supply chains.

Importance of Tamper-Evident Solutions

Tamper-evident packaging serves several critical functions:

Tamper-evident packaging protects consumers from potentially harmful tampered products by showing visible evidence if a package has been opened. It maintains product integrity from manufacturing to consumption, making sure medications remain unchanged throughout the supply chain. These packages provide visual proof of tampering through permanent changes to packaging when someone tries to open it. They also meet regulatory requirements, including FDA rules that require tamper-evident features for over-the-counter medications. Finally, they build consumer trust by showing the manufacturer cares about safety and security.

Regulatory standards, including those from the FDA and EU Falsified Medicines Directive, require tamper-evident features for many pharmaceutical products. These regulations have become stricter after incidents of product tampering and counterfeiting. The Falsified Medicines Directive requires both tamper-evident features and unique identifiers on prescription medications, creating multiple layers of protection.

Our security labels provide reliable tamper evidence through features like void messaging, which shows "VOID" or "OPENED" text when someone tries to remove the label. These labels get permanently damaged if someone tries to remove them, providing clear visual evidence of tampering. The special adhesives and materials ensure that any attempt to remove and reapply them will result in visible damage.

Advanced Security Features for Anti-Counterfeiting

Beyond basic tamper evidence, pharmaceutical labels often include sophisticated security features to fight counterfeiting:

- Holographic elements that are hard to copy and create distinctive visual effects that change when viewed from different angles

- Microtext and hidden images visible only with magnification, providing a secret authentication method

- Colour-shifting inks that change appearance when viewed from different angles

- Serialisation and unique identifiers for tracking products throughout the supply chain

- QR codes linking to verification systems that allow real-time authentication via smartphone

Labelprint24 offers holographic security labels that include multiple anti-counterfeiting features. These labels protect products and enhance brand reputation by showing a commitment to product security and consumer safety. Our holographic elements combine visible and hidden security features, creating multiple layers of protection that are hard to copy.

Using serialisation systems, which give unique identifiers to individual packages, has become increasingly important in pharmaceutical labelling. These systems support tracking capabilities that help prevent diversion and verify product authenticity throughout the supply chain. Both European and US regulations now require serialisation for prescription medications, creating a global framework for pharmaceutical authentication that relies on sophisticated labelling technologies.

Multi-Layer and Extended Content Labels

Space limits create big challenges for pharmaceutical labelling. With extensive information requirements but limited packaging space, manufacturers need innovative labelling solutions. Multi-layer label technology has changed how the pharmaceutical industry presents information, allowing for comprehensive content without making packages bigger or less attractive.

Benefits of Booklet and Multi-Page Labels

Multi-layer labels offer several advantages for pharmaceutical products:

Multi-layer labels provide expanded content space without increasing package size, letting manufacturers include comprehensive information on small containers. They can include information in multiple languages, helping with global distribution while meeting regulations in different markets. They provide room for detailed instructions and comprehensive warnings, including expanded patient information. They create space for regulatory information alongside marketing content. And they reduce the need for separate package inserts, streamlining packaging and reducing waste.

Our booklet labels are specially designed to meet the demanding requirements of pharmaceutical products. These labels provide multiple pages of content while looking professional and meeting regulatory standards. The innovative design allows for easy opening and reclosing, making sure information remains accessible throughout the product's lifecycle while maintaining package integrity.

The construction of multi-layer labels requires careful consideration of materials and adhesives. Labels must be easy to open and reclose while remaining securely attached to the product. Labelprint24's multi-layer labels feature durable materials and reliable adhesives that maintain integrity throughout the product lifecycle. Our engineering process considers factors like container curvature, surface texture, and environmental exposures to ensure labels remain functional and legible in real-world conditions.

Implementation Considerations

- Ease of opening and reclosing for end-users, especially important for patients with limited dexterity or visual impairments

- Durability of hinges and connection points, which must withstand repeated opening and closing without tearing

- Compatibility with automated application equipment, ensuring efficient manufacturing

- Resistance to environmental conditions, including moisture, temperature changes, and handling

- Readability of all content layers, maintaining consistent print quality throughout the label

Our three-page multi-layer labels are designed with these considerations in mind. They feature durable construction, clear opening instructions, and high-quality printing on all pages to ensure information remains accessible and legible throughout the product's life. The special adhesives maintain their performance across a wide range of temperatures and humidity levels, ensuring reliable attachment even in challenging environments like refrigerators or humid settings.

The design of multi-layer labels also requires careful planning of content organisation. Information should be logically structured, with the most critical details appearing on the outer layer and additional information on inner pages. This approach ensures that essential safety information remains immediately accessible. Working with regulatory experts during the design phase helps ensure that the content organisation complies with regulations while optimising readability and usability.

Regulatory Compliance for Chemical Components

Many pharmaceutical products contain chemical components that require specific labelling under GHS (Globally Harmonised System) and CLP (Classification, Labelling and Packaging) regulations. These standards ensure consistent hazard communication across different countries and regions. These globally harmonised systems have improved safety communication while making international trade easier by standardising hazard communication elements.

GHS/CLP Labelling Requirements

Key elements of GHS/CLP compliant labels include:

GHS/CLP compliant labels need hazard pictograms that visually show specific dangers through standardised symbols in red diamond borders. They use signal words ("Danger" or "Warning") to indicate how severe the hazard is, with "Danger" used for more serious hazards. They include hazard statements describing the nature of hazards in standardised phrases that are consistent across languages. They provide precautionary statements advising on safe handling, storage, disposal, and emergency response. And they include supplier identification information with name, address, and emergency contact details.

Labelprint24's chemical labels are specially designed to meet these regulatory requirements. Our labels are durable and resistant to chemicals, ensuring that critical hazard information remains legible even when exposed to the substances being labelled. The special materials resist fading, smearing, and degradation, maintaining the integrity of safety information throughout the product's lifecycle, even in settings where exposure to solvents or other harsh chemicals is possible.

The placement of GHS/CLP elements on pharmaceutical labels requires careful consideration. These elements must be prominently displayed and clearly visible, often requiring specific label designs that accommodate both regulatory symbols and product information. The integration of these standardised elements with brand-specific design elements and other required information requires thoughtful layout planning to ensure compliance while maintaining aesthetic appeal and brand consistency.

Material Requirements for Chemical Labels

- Resist degradation from chemical exposure, maintaining integrity even when in contact with aggressive substances

- Maintain adhesion even when in contact with solvents or acids, preventing label detachment that could result in lost safety information

- Prevent ink bleeding or fading when exposed to chemicals, ensuring that hazard information remains clear and legible

- Withstand laboratory or manufacturing environments, including exposure to temperature changes, humidity, and mechanical stress

Our chemical labels are made using specialised materials designed to withstand these challenging conditions. The combination of durable face stocks, chemical-resistant adhesives, and protective coatings ensures that critical safety information remains intact and legible throughout the product's lifecycle. These materials undergo thorough testing to verify their performance under various chemical exposure scenarios, ensuring reliable performance in real-world applications where label failure could have serious safety implications.

For pharmaceutical manufacturers handling hazardous chemicals, proper labelling is not just a regulatory requirement but a critical safety measure. Clear, durable chemical labels help prevent accidents, ensure proper handling, and protect both workers and end-users from potential harm. Using consistent, compliant chemical labelling also supports efficient operations by reducing confusion and promoting standardised handling procedures across different facilities and regions.

Packaging Solutions for Pharmaceutical Products

Beyond labels, pharmaceutical packaging itself plays a crucial role in product protection, compliance, and brand presentation. The right packaging solution can enhance product security while making proper labelling easier. The integration of packaging and labelling strategies creates a comprehensive approach to pharmaceutical product presentation that balances regulatory requirements, functional needs, and marketing considerations.

Folding Cartons and Boxes

Folding cartons are among the most common packaging solutions for pharmaceutical products, offering several advantages:

Folding cartons provide plenty of surface area for required labelling information, allowing for clear presentation of dosage instructions, warnings, and other critical details. They protect primary containers (bottles, blisters, etc.) from light, moisture, and physical damage during distribution and storage. They provide space for tamper-evident features and security elements, including seals, perforations, and authentication devices. They offer professional presentation that builds brand recognition through consistent design elements, colour schemes, and typography. And they can be customised to accommodate different product sizes, dosage forms, and quantity configurations.

Labelprint24 offers a range of folding boxes with hinged lids that are ideal for pharmaceutical applications. These boxes provide secure closure while allowing easy access to the contents. The hinged design ensures that important label information remains intact even after multiple openings. The specialised construction features reinforced stress points and precise folding geometries that maintain structural integrity throughout the product's lifecycle, even with frequent opening and closing.

Our carrying handle boxes with snap-lock bases offer additional convenience for larger pharmaceutical products or multi-pack configurations. The double cardboard layer on the handle provides excellent stability, while the simple assembly with plug-in straps makes these boxes efficient to produce and fill. These innovative designs balance structural integrity with user-friendly features, creating packaging solutions that protect products while enhancing the consumer experience through thoughtful design.

Specialised Packaging Considerations

- Child-resistant closures for potentially harmful products, designed to be difficult for young children to open while remaining accessible to adults

- Senior-friendly designs that balance safety with accessibility, addressing the needs of older patients who may have limited dexterity or strength

- Light-protective materials for photosensitive products, including amber-coloured glass or opaque plastics that filter harmful light

- Moisture barriers for water-sensitive formulations, using materials with low water vapour transmission rates

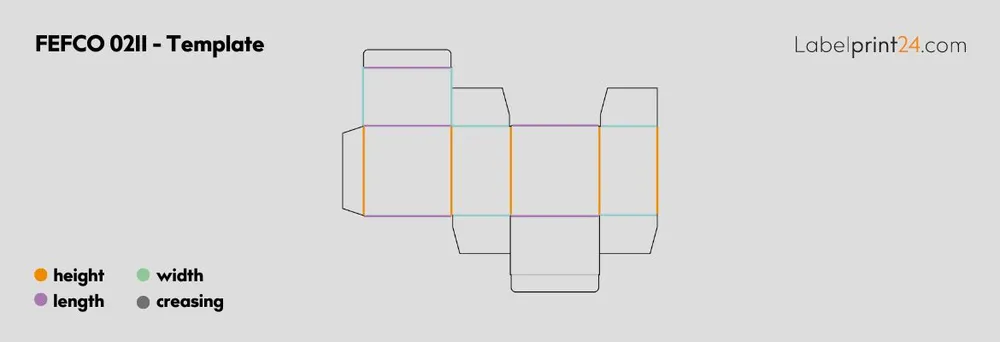

Our FEFCO 0211 folding boxes provide a versatile solution that can be customised to meet various pharmaceutical packaging requirements. These boxes feature a tuck-in flap design that offers easy opening and secure closure, making them suitable for a wide range of pharmaceutical products. The standardised construction can be adapted to incorporate specialised features like child-resistant mechanisms or senior-friendly opening systems, providing a flexible platform for diverse pharmaceutical packaging needs.

When designing pharmaceutical packaging, it's essential to consider the entire product lifecycle, from manufacturing and distribution to patient use and disposal. Packaging must maintain its integrity throughout this journey while facilitating proper labelling and ensuring that critical information remains accessible to end-users. Sustainable materials and designs are increasingly important, balancing environmental responsibility with the strict performance requirements of pharmaceutical packaging.

Digital Printing Technologies for Pharmaceutical Labels

Advanced printing technologies play a crucial role in meeting the high standards required for pharmaceutical labelling. Digital printing offers particular advantages for this demanding application, providing the precision, flexibility, and quality control capabilities essential for regulatory compliance and product safety.

Advantages of Digital Printing for Compliance

Digital printing provides several benefits for pharmaceutical label production:

Digital printing offers exceptional print quality for fine text and barcodes, ensuring that even the smallest regulatory text remains crisp and legible. It allows incorporation of variable data for serialisation, enabling unique identifiers on each label for tracking compliance. It provides consistent colour reproduction for brand elements and warning symbols, maintaining standardised appearances across production runs. It makes short runs cost-effective for product variations or language versions, eliminating the need for large inventory of pre-printed labels. And it enables rapid turnaround for urgent compliance updates, allowing quick implementation of regulatory changes or safety information updates.

Labelprint24 offers thermal transfer wax ribbons that deliver exceptional print quality for pharmaceutical labels. These ribbons produce crisp, durable imprints that resist smudging and fading, ensuring that critical information remains legible throughout the product's lifecycle. The special formulation of these ribbons provides excellent adhesion to a wide range of label materials, creating permanent, high-contrast images that maintain their integrity even when exposed to handling, moisture, or moderate chemical contact.

For pharmaceutical manufacturers, the ability to produce small batches of labels is particularly valuable. Digital printing eliminates the need for expensive printing plates, making it economical to produce the exact quantity needed for each production run. This flexibility also makes it easy to respond quickly to regulatory changes or product updates. When safety information needs to be changed or regulatory agencies require labelling changes, digital printing allows for immediate implementation without wasting large inventories of outdated pre-printed labels.

Variable Data and Serialisation

- Unique identifiers can be printed on each label, supporting compliance with serialisation requirements like the EU Falsified Medicines Directive

- QR codes or barcodes can link to verification systems, enabling authentication through smartphone apps or dedicated scanners

- Lot numbers and expiration dates can be updated between print runs without changing the entire label design

- Regional variations can be accommodated without changing the entire label design, supporting efficient global distribution

Our thermal transfer printing solutions support these variable data requirements, enabling pharmaceutical manufacturers to implement robust serialisation and authentication systems. The combination of high-quality printing with secure label materials creates a comprehensive solution for product identification and verification. These systems can generate and apply unique identifiers at production speeds, maintaining manufacturing efficiency while implementing sophisticated anti-counterfeiting measures that protect both consumers and brand integrity.

The integration of printing systems with data management platforms is increasingly important for pharmaceutical labelling. These integrated systems ensure data integrity throughout the printing process, maintaining the chain of custody for product information from design to application. Modern serialisation solutions incorporate database management, verification portals, and reporting tools that work with printing technologies to create complete track-and-trace systems.

Labelling Machines and Application Systems

Consistent label application is essential for pharmaceutical products. Automated labelling machines ensure precise placement while maintaining production efficiency. The selection and validation of appropriate labelling equipment is a critical aspect of pharmaceutical manufacturing, directly impacting both compliance and operational performance.

Selecting the Right Labelling Equipment

When choosing labelling equipment for pharmaceutical applications, several factors must be considered:

When selecting labelling equipment, you need to consider label size and shape compatibility, ensuring that the equipment can handle the specific dimensions and configurations required for different products. You must account for container types and dimensions, accommodating various shapes from flat cartons to round bottles or irregularly shaped containers. Production speed requirements must balance throughput needs with precision placement capabilities. Validation and qualification capabilities should support the documentation and testing required for GMP compliance. And the equipment should integrate with existing production lines, ensuring seamless operation within the overall manufacturing process.

Labelprint24 offers labelling machines designed specifically for pharmaceutical applications. These machines provide precise label placement while maintaining the high throughput required in pharmaceutical manufacturing environments. Our equipment features advanced control systems that ensure consistent placement accuracy, even at high production speeds, maintaining compliance with strict pharmaceutical labelling requirements for positioning and orientation.

For maximum efficiency, labelling machines should be compatible with the specific label formats used in pharmaceutical applications. Our machines are designed to work seamlessly with various label types, including standard pressure-sensitive labels, multi-layer constructions, and security labels with special features. This versatility allows pharmaceutical manufacturers to implement sophisticated labelling strategies without compromising production efficiency. The modular design of our equipment makes quick changeovers between different product formats easy, minimising downtime and maximising manufacturing flexibility.

Validation and Quality Control

- Installation Qualification (IQ) to verify proper installation, documenting that all components are correctly installed and configured according to specifications

- Operational Qualification (OQ) to confirm operation within specifications, testing all functions across their operational ranges

- Performance Qualification (PQ) to demonstrate consistent performance under actual production conditions over extended periods

- Ongoing verification through regular maintenance and calibration, ensuring continued compliance throughout the equipment's lifecycle

Quality control systems for label application should include vision inspection to verify label presence, position, and readability. These systems can detect issues such as wrinkles, bubbles, or misalignment that might compromise label effectiveness or regulatory compliance. Modern inspection systems use high-resolution cameras and sophisticated image processing algorithms to identify defects that might be invisible to the human eye, providing comprehensive quality assurance for every labelled product. These automated inspection capabilities are particularly important for pharmaceutical products, where label defects could potentially impact patient safety by hiding critical information or dosage instructions.

Labelprint24's labelling solutions include comprehensive validation documentation and support services to help pharmaceutical manufacturers meet regulatory requirements. Our team works closely with clients to ensure that labelling systems are properly validated and maintained throughout their operational life. This collaborative approach includes development of validation protocols, execution of qualification testing, and creation of detailed documentation that satisfies regulatory requirements. Our ongoing support services help maintain system performance and compliance, with regular maintenance, calibration, and updates as needed.

Compliance with International Regulations

Pharmaceutical products are often distributed globally, requiring compliance with multiple regulatory frameworks. Understanding these international requirements is essential for successful product labelling. The complexity of dealing with diverse regulatory landscapes requires sophisticated approaches to label design and management that accommodate regional variations while maintaining operational efficiency.

Major Regulatory Frameworks

Key regulatory frameworks affecting pharmaceutical labelling include:

FDA (U.S. Food and Drug Administration) requirements include specific content, format, and readability standards for prescription and over-the-counter medications. EU Falsified Medicines Directive and Medical Device Regulation mandate serialisation, anti-tampering features, and specific safety information. Health Canada regulations include bilingual labelling requirements and unique Canadian symbol systems. Japan's PMDA (Pharmaceuticals and Medical Devices Agency) standards feature specific requirements for Japanese language presentation and cultural considerations. ICH (International Council for Harmonisation) guidelines aim to standardise certain aspects of pharmaceutical information across regions.

While these frameworks share common goals of ensuring product safety and effectiveness, they often differ in specific requirements. These differences can include required warning statements, symbol usage, information formatting, and language requirements. For example, the EU requires certain standardised statements and symbols that differ from US requirements, while Canadian regulations require bilingual (English and French) content on all pharmaceutical labels. These regional variations create significant challenges for global pharmaceutical companies trying to maintain consistent branding while meeting diverse regulatory requirements.

Labelprint24 works with pharmaceutical companies to create compliant label designs that meet the requirements of multiple regulatory frameworks. Our expertise in international regulations helps clients navigate complex compliance landscapes while maintaining consistent brand presentation. Our design approach incorporates modular elements that can be adapted for different markets without compromising the overall label architecture, creating efficient solutions for global distribution while ensuring that each regional variant fully complies with local requirements.

Strategies for Global Compliance

- Developing harmonised label templates that accommodate regional variations while maintaining consistent brand presentation and information architecture

- Using multi-layer labels to include information for multiple markets, with dedicated sections or pages for region-specific content

- Implementing variable data printing for region-specific elements, allowing customisation of certain label components during production

- Creating modular label designs where only certain elements change between regions, minimising the need for completely different designs

Quality Assurance and Validation in Pharmaceutical Labelling

Quality assurance represents the cornerstone of pharmaceutical labelling operations, ensuring that every label meets stringent regulatory requirements whilst maintaining consistent performance throughout the product lifecycle. The pharmaceutical industry's commitment to patient safety demands comprehensive validation processes that verify not only label content accuracy but also material performance, application reliability, and long-term durability under real-world conditions.

Validation Protocols and Testing Requirements

Pharmaceutical labelling validation encompasses multiple critical areas that must be systematically addressed to ensure compliance and performance. Label material testing forms the foundation of this process, evaluating adhesive performance across expected temperature ranges, humidity conditions, and chemical exposures. Materials must demonstrate consistent adhesion without degradation, ensuring that labels remain securely attached throughout storage, distribution, and patient use whilst maintaining removability when required for regulatory compliance or safety reasons.

Print quality validation ensures that all information remains legible and accurate throughout the product's shelf life. This includes testing print durability under various environmental conditions, verifying barcode readability after exposure to handling and environmental stresses, and confirming that colour reproduction meets brand standards and regulatory requirements for warning symbols. Advanced testing protocols simulate real-world conditions including transportation vibration, temperature cycling, and exposure to common cleaning agents or sterilisation processes.

Labelprint24's thermal transfer printing solutions undergo rigorous testing to ensure consistent performance in pharmaceutical applications. Our materials are validated across a wide range of environmental conditions, providing pharmaceutical manufacturers with documented evidence of performance that supports regulatory submissions and compliance audits. This comprehensive testing approach includes accelerated ageing studies, chemical resistance evaluations, and mechanical stress testing that simulates years of real-world exposure.

Good Manufacturing Practice (GMP) Compliance

GMP compliance in pharmaceutical labelling extends beyond basic quality control to encompass comprehensive systems that ensure consistent, traceable, and validated operations. This includes maintaining detailed batch records for all labelling materials, implementing change control procedures that document and approve any modifications to labelling specifications, and establishing regular audit procedures that verify ongoing compliance with established protocols.

Personnel training represents a critical component of GMP compliance, ensuring that all individuals involved in labelling operations understand their roles in maintaining product quality and regulatory compliance. Training programmes must cover not only technical procedures but also the critical importance of labelling accuracy in patient safety. Regular competency assessments and refresher training help maintain high standards throughout the organisation.

- Batch record maintenance with complete traceability from raw materials through finished labels

- Environmental monitoring to ensure labelling areas meet pharmaceutical standards

- Equipment qualification and ongoing calibration programmes

- Deviation investigation and corrective action procedures

- Regular internal audits and management reviews

Our security labelling solutions are manufactured under controlled conditions that meet pharmaceutical industry standards. We provide comprehensive documentation packages that support GMP compliance, including certificates of analysis, material safety data sheets, and validation support documentation. This thorough approach ensures that our clients can confidently integrate our solutions into their validated systems whilst maintaining full regulatory compliance.

Risk Management and Continuous Improvement

Effective pharmaceutical labelling operations require robust risk management systems that identify potential issues before they impact product quality or patient safety. Risk assessments should evaluate all aspects of the labelling process, from material selection and supplier qualification through production processes and final product release. These assessments help prioritise quality control activities and establish appropriate monitoring systems for critical parameters.

Continuous improvement initiatives ensure that labelling systems evolve to meet changing requirements and incorporate advancing technologies. This includes regular review of labelling materials and processes, evaluation of new technologies that might enhance quality or efficiency, and ongoing assessment of regulatory developments that might impact labelling requirements. Feedback from field experience, customer complaints, and regulatory inspections provides valuable input for improvement initiatives.

At Labelprint24, we support our pharmaceutical clients through comprehensive quality partnerships that extend beyond simple product supply. Our technical teams work closely with clients to optimise labelling processes, troubleshoot challenges, and implement improvements that enhance both quality and efficiency. This collaborative approach ensures that labelling systems continue to meet evolving requirements whilst supporting operational excellence throughout the product lifecycle.

Conclusion: Building a Comprehensive Pharmaceutical Labelling Strategy

Pharmaceutical labelling represents one of the most complex and critical aspects of bringing medical products to market safely and legally. The intricate web of regulatory requirements, technical specifications, and safety considerations demands a comprehensive approach that balances compliance with practicality. Success in pharmaceutical labelling requires understanding that labels are not merely information carriers—they are integral safety devices that protect patients, support healthcare providers, and maintain product integrity throughout the supply chain.

The evolution of pharmaceutical labelling continues to accelerate, driven by advancing technologies, changing regulatory landscapes, and growing emphasis on patient safety and product authentication. Multi-layer label solutions, advanced printing technologies, and sophisticated security features have transformed what was once a simple identification process into a sophisticated communication system. These innovations enable pharmaceutical manufacturers to meet expanding information requirements whilst maintaining package efficiency and visual clarity.

At Labelprint24, we recognise that pharmaceutical labelling success requires more than just technical compliance—it demands a partnership approach that considers the entire product lifecycle. From initial label design through global distribution and patient use, every element must work harmoniously to ensure safety, compliance, and brand integrity. Our comprehensive range of booklet labels, security solutions, and chemical-resistant labels provides pharmaceutical manufacturers with the tools needed to meet today's complex requirements whilst preparing for tomorrow's challenges.

The future of pharmaceutical labelling will likely see continued integration of digital technologies, enhanced serialisation capabilities, and more sophisticated anti-counterfeiting measures. Smart labels incorporating NFC or RFID technology may become commonplace, providing real-time authentication and patient interaction capabilities. However, the fundamental principles of clear communication, regulatory compliance, and patient safety will remain constant. Manufacturers who invest in robust labelling systems today—incorporating quality materials, advanced printing technologies, and comprehensive validation processes—will be well-positioned to adapt to these emerging requirements.

Successful pharmaceutical labelling also requires ongoing attention to regulatory changes and industry best practices. Regulatory agencies continuously update requirements in response to new safety data, technological capabilities, and global harmonisation efforts. Staying ahead of these changes requires not just compliance monitoring but active engagement with industry developments and regulatory guidance. This proactive approach ensures that labelling strategies remain current and that product launches aren't delayed by unexpected regulatory requirements.

For pharmaceutical manufacturers seeking to optimise their labelling strategies, the key lies in viewing labels as integrated systems rather than individual components. The interaction between materials, printing technologies, application methods, and regulatory requirements creates a complex ecosystem that demands expert navigation. Labelprint24's comprehensive solutions—from specialised packaging solutions to advanced multi-layer labelling systems—provide the foundation for building labelling strategies that protect patients, satisfy regulators, and support business objectives.

Your Next Steps for Pharmaceutical Labelling Excellence

Ready to enhance your pharmaceutical labelling strategy? Contact Labelprint24's expert team to discuss your specific requirements and discover how our comprehensive solutions can support your compliance goals whilst optimising operational efficiency. Our pharmaceutical labelling specialists understand the unique challenges you face and can provide tailored recommendations that address your exact needs, from material selection and regulatory compliance to equipment validation and ongoing support.

The pharmaceutical industry's commitment to patient safety and product quality drives continuous innovation in labelling technologies and practices. By partnering with experienced providers who understand both current requirements and future trends, pharmaceutical manufacturers can build labelling systems that not only meet today's challenges but adapt to tomorrow's opportunities. Excellence in pharmaceutical labelling isn't just about compliance—it's about creating comprehensive communication systems that protect patients, support healthcare providers, and maintain the integrity of life-saving medicines throughout their journey from manufacturer to patient.