Printed labels

Printed labels

Are you looking for a label that is opaque, numbered or metallised? A label that is suitable for thermal printing and frozen goods? Printed labels from Labelprint24.com mark your products individually and professionally.

- Fast production and free delivery

- State-of-the-art production for best quality

- Wide range of label accessories

Choose your product and calculate it directly online!

- Production TimeStarting from 2 days

- MaterialFilm / Paper

- Size100% customizable

- OptionFilm finishing / Varnish

Select kind of product

What are printed labels?

Printed labels are labels on a roll, which are often also called adhesive roll labels, stickers, adhesive labels, roll labels, bottle labels or self-adhesive labels. Adhesive labels are used universally, especially on bottles, cans, jars, printed packaging and other containers. The industrial sectors can be very different. They range from the chemical, food and beverage industries to the cosmetics industry and many more. Depending on the intended use, printed labels must be short- or long-lasting, suitable for food, water- and scratch-resistant, uv-resistant as well as chemical-resistant.

Sample made to measure. Simply order online.

The sample box from Labelprint24 offers you an exclusive selection of products, printed and finished in our company design. We will refund the full purchase price of the sample box in the form of a voucher if you decide to order from Labelprint24. The voucher is of course valid for all products in our webshop.

In this box you will find samples of labels, folding boxes, laminate tubes and package inserts.

Printed labels fit into manual or automatic label dispensers that have a rotating dispensing system, allowing for high sticking speeds. Printed labels on rolls guarantee the required speed, secure adhesion and operational economy: these three factors are crucial for industrial labelling with adhesive labels and stickers. Labels on rolls are used as roll labels or sheet labels in all industrial sectors, at authorities, universities, in the office or at home.

You will find labels on rolls in all common formats and materials at Labelprint24. From paper to film labels, as well as permanently adhesive and removable labels.

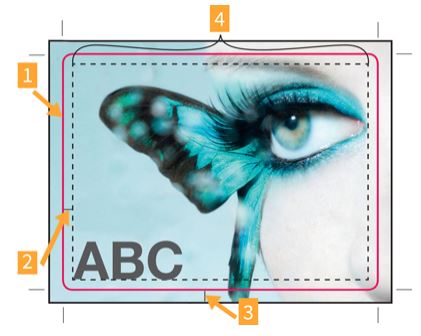

Artwork requirements for labels on roll

1. Applying labels on rolls

- food labelling

- numbered barcode labels in the transport and logistics industries

- transport stickers for labelling containers of chemicals

- weather-resistant foil labels for the chemical and automotive industries

- signage on technical components

- glossy labels and transparent stickers for cosmetics

- Foodstuffs are most often labelled under the most difficult conditions, such as wet or greasy conditions or freezing temperatures. The food industry is particularly sensitive, with many legal requirements such as REACH, food labelling laws, and product information laws (LMIV). It is also necessary to ensure that no or only a very minimal amount of microscopic components in the pressure-sensitive adhesive label material makes its way into the food product.

- For most products used in the chemical industry an approval according to "British Standard 5609 Section 2" is mandatory. This means that the printed labels must be able to be stored for up to three months in saltwater without peeling during transport on container ships.

2. Digital or conventionally printed labels

- Label order volume

- Label material

- Additional features of the labels

- Requirements for personalization

3. Materials for roll labels

3.1 Label paper

3.2 Metallicised paper labels

3.3 Fluorescent paper labels

3.4 Printed labels made of thermal paper

3.5 Printed labels on plastic film

3.6 Backing material

4. Processing and finishing

5. Winding labels on the roll core

6. Dispensing labels

6.1 Manual dispensers for printed roll labels

Handheld dispensers feed the printed roll labels by pressing a lever on the handle. A rubber roll peels off the individual label and applies it. This method works quite quickly but is still far too inaccurate and too slow for large quantities of labels.